6

1. SYMBOLS

Below follows a short legend with an indication of

the symbols used throughout the manual (those

considered most significant).

WARNING

DANGER:

Draws

the

attention to situations or problems

which may cause injury to persons or

risk of death.

IMPORTANT: Draws the attention to

situations or problems connected with

machine efficiency but which do not

pose a risk to the safety of persons.

The following instructions are indicated on the

machine (Fig. 2):

No.

Description

1

Danger:

•

Carefully read the instruction manual.

• Do not let unauthorised persons come near the

working area.

• Carry out maintenance work only when the machine is

off and after having pulled out the key and read the

instruction manual.

• Do not remove the protection and safety devices.

• Rotating parts: Risk of injuring the limbs.

• Hot surfaces: risk of burns

• Rotating tools: risk of injuring the limbs.

2

Protect hearing with earmuffs

3

CE plate

Observe the warnings on the plates.

Inobservance may cause death or injury

to the personnel. Ensure that the plates

are always present and legible. If

otherwise, apply or replace them.

2. GENERAL PRECAUTIONS FOR

USE

The

operator

is

personally

responsible for the operating safety

of the machine.

Carefully read this manual before

starting, use, maintenance or other

operations on the machine.

The purpose of this manual is to

bring to the attention of the

operator, with illustrations and

texts, the fundamental instructions

and the criteria to follow for use and

maintenance of the machine.

In order to operate in safety:

Check that the machine has not

been damaged during transport,

and if so, immediately notify the

manufacturer

or

the

area

representative.

Allow only authorised personnel

to use the machine.

Operators not working on the

machine must keep the safety

distance when the machine is

running.

Periodically clean the machine,

removing any foreign materials

which may compromise operation

or cause injury to the operator.

Before using the machine, ensure

that all the protection devices are

properly in place and in good

working order.

Should the protection devices be

faulty or damaged, replace them

immediately.

Carry out maintenance work only

after having read the instruction

manual and having pulled out the

ignition key or detaching the spark

plug.

Any repairs should exclusively be

carried out by qualified personnel

using

original

spare

parts.

Otherwise the user may be

exposed to serious risk.

Do not wear clothes that may get

caught up in moving parts such as

loose-fitting garments, scarves,

coats, etc. It is recommended to

wear

approved

garments

for

accident-prevention purposes, for

example:

Hard

hats,

anti-slip

shoes, earmuffs, safety goggles,

heatproof gloves, safety mask.

Ask your employer about the

safety regulations in force and the

safety devices

.

Summary of Contents for 1830041

Page 3: ...3...

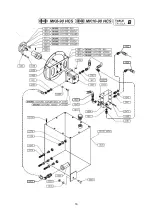

Page 14: ...14 7 11 Parts List...

Page 15: ...15...

Page 16: ...16...

Page 17: ...17...

Page 18: ...18...

Page 19: ...19...

Page 20: ...20...

Page 21: ...21...

Page 22: ...22...

Page 23: ...23...

Page 24: ...24...

Page 25: ...25...

Page 26: ...26...

Page 27: ...27...

Page 28: ...28...

Page 29: ...29...

Page 30: ...30...

Page 31: ...31...

Page 32: ...32...

Page 33: ...33...

Page 34: ...34...

Page 35: ...35...

Page 36: ...36...

Page 37: ...37...

Page 38: ...38...

Page 39: ...39...

Page 40: ...40...

Page 41: ...41...

Page 42: ...42...

Page 43: ...43...

Page 44: ...44...

Page 45: ...45...

Page 46: ...46...

Page 47: ...47...

Page 48: ...48...

Page 49: ...49...

Page 50: ...50...

Page 51: ...51...

Page 52: ...52...

Page 55: ...55 NOTES...