9

The machine handling operations must

be carried out in observance of the

regulations in force regarding safety in

the workplace.

Dispose of the packaging in the

appropriate manner in accordance with

the regulations in force in the country of

use.

4.2.

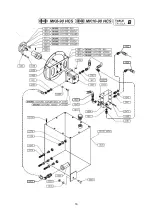

Component Assembly

Seat Assembly

: Attach the seat (1) Fig. 3 to the

support plate (2) using the 4 bolts. Fully tighten

the nuts and connect the terminal (3) to the seat

cable (4).

Headlight Assembly

: Fit the headlight (Fig. 1 No.

12) in such a way that it is tight enough to resist

rotation and movement. Fit the ground cable,

screw on and tighten the counternut and fit the

power cable (6) into the plugs (Fig. 8).

Battery Cable Connection

: Remove the cover

and connect the relevant cable to the positive pole

(Fig. 9 No. 2) of the battery (1), appropriately

tightening the terminal.

4.3.

Water Supply

The hydraulic float machine MK8 90 has an

autonomous wetting system. The water is sprayed

in correspondence to the rotors from the nozzles

connected to the water tank.

When filling the tank, be careful not to confuse the

water tank (Fig. 2 No. 9) with the fuel tank (Fig. 1

No. 8).

4.4.

Fuel

WARNING

:

Danger of explosion and

fire.

Fill the tank in an open place away from

heat sources. Do not smoke. Do not

refuel when the engine is running or hot.

IMPORTANT:

Consult the engine manual for the type

of fuel to use.

1.

Clean the area around the fuel filler cap.

2.

Remove the cap.

3.

Fill the tank up to 3-4 cm from the brim in

order to allow the fuel to expand.

4.

Close the filler cap.

5.

Always thoroughly clean the area around

the cap removing any spills.

4.5.

Engine Oil

Refer to the engine manual.

Dispose of used oil in the appropriate

manner

in

accordance

with

the

regulations in force in the country of use.

5. USE

5.1.

Preliminary Checks

Before proceeding with starting and use of the

float machine, do the following:

1. Check the oil level in the engine and, if

necessary, top off (see Par. 4.5).

2. Check the fuel level in the tank and, if

necessary, refuel (see Par. 4.4).

3. Check that all the protection devices are

present and working.

4. Adjust the seat position horizontally to

obtain the best possible working position

(see Par. 3.4).

5. Check that the blade is inclined by at least

1 cm in order to have better control over

the float machine when starting (for

adjustment see Par. 3.5).

6. Ensure

that

the

float

machine

is

positioned on a flat surface with a

capacity of more than 300 kg/m

2

and that

there is sufficient space around the float

machine (at least 2 m).

5.2.

Starting

In order to prevent slippage and losing

control of the float machine when

starting and during the working phases

the operator must be seated in the

driver’s seat on the float machine and

always holding the accelerator pedal in

the idle position.

To start the float machine, operate as follows:

1.

Sit in the driver’s seat after appropriately

adjusting its position and with the feet

resting on the footboard.

2. Close the choke (for petrol-powered

engine only).

3. Position the accelerator hand-lever or

accelerator pedal (Fig. 1 No. 5) in the idle

position.

4. Turn the ignition key.

5. After starting, open the choke (for petrol-

powered engines only).

The engine is started at reduced rpm, the clutch

Summary of Contents for 1830041

Page 3: ...3...

Page 14: ...14 7 11 Parts List...

Page 15: ...15...

Page 16: ...16...

Page 17: ...17...

Page 18: ...18...

Page 19: ...19...

Page 20: ...20...

Page 21: ...21...

Page 22: ...22...

Page 23: ...23...

Page 24: ...24...

Page 25: ...25...

Page 26: ...26...

Page 27: ...27...

Page 28: ...28...

Page 29: ...29...

Page 30: ...30...

Page 31: ...31...

Page 32: ...32...

Page 33: ...33...

Page 34: ...34...

Page 35: ...35...

Page 36: ...36...

Page 37: ...37...

Page 38: ...38...

Page 39: ...39...

Page 40: ...40...

Page 41: ...41...

Page 42: ...42...

Page 43: ...43...

Page 44: ...44...

Page 45: ...45...

Page 46: ...46...

Page 47: ...47...

Page 48: ...48...

Page 49: ...49...

Page 50: ...50...

Page 51: ...51...

Page 52: ...52...

Page 55: ...55 NOTES...