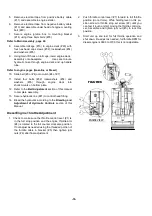

EXCITER WEIGHTS

ROTATED AS SHOWN

HUB OF IDLER GEAR

OPPOSITE SHAFT

SHOULDER

TIMING MARK LOCATION

BASEPLATE GEAR TIMING

HELIX PIN ORIENTED

HORIZONTALLY

HYDRAULIC HOUSING

SIDE OF BASEPLATE

FIGURE 5

Mettre l'extrémité de l'arbre avec le trou vers le

côté avant droit de la machine côté reniflard (#18).

11. Installer le support d'arbre (#7) côté poulie, et

(#18) côté hydraulique. Fixer chaque support

avec vis à tête hexagonale (#23) en utilisant

LOCTITE #243 sur le filetage et serrer avec un

couple de 17kN

Voir le shéma #3 pour

l'application de LOCTITE #515. Laisser un jeu

de 0.5mm minimum pour l'arbre de renvoie une

fois que les vis sont installées et serrées au

couple

12. Installer le raccord à 90° (#2) contenant la broche à

rouleau (#20) dans le support de l'arbre (#18) en

utilisant LOCTITE #565 sur les filetages.

Assurez

vous que le support reniflard soit dirigé vers le

haut de la semelle

13. Installer le reniflard (#3) sur le raccord 90° (#2)

14. Install the exciter weights (#17) on the idler shaft (#8)

and secure with four socket head cap screws (#24)

using LOCTITE #243 thread locker sealant and

torque the cap screws to 32 ft.-lbs.

15. Press one bearing inner race onto one end of the

input shaft (#16).

Note: Make sure the bearings

and their inner races are kept as a matched set.

The flange on the inner race goes toward the

shoulder of the shaft.

16. Install the input gear (#10) onto the input shaft (#16)

and slide to the end with the bearing inner race.

17. Press the other bearing inner race onto the input

shaft (#16).

18. Install the input shaft subassembly into the baseplate

with the keyed end toward the left side (pulley side)

of the base plate.

19. Install the pulley side shaft cover (#9), containing the

shaft seal (#5) over the input shaft on the pulley side

of the baseplate.

See the figure #3 for LOCTITE

#515 gasket maker application. Lubricate the

input shaft seal and bearing with exciter oil

before inserting the input shaft through the oil

seal in the cover to prevent tearing the seal.

20. Secure the input shaft cover with the four flange head

crews (#23) using LOCTITE #243 thread locker

sealant on the bolt threads and torque the capscrews

to 13 ft.-lbs.

Refer to LOWER SHAFT ASSEMBLY, page 30.

21. Install the other input shaft cover (#12) and secure

with the four flange head screws (#22) using

LOCTITE #243 thread locker sealant and torque the

screws to 13 ft.-lbs.

See the figure #3 for LOCTITE

#515 gasket maker application. Check input

shaft for minimum of .020” end play after covers

are installed and the bolts are torqued.

22. Install one exciter weight (#17) to the input shaft on the

hydraulic housing side of the baseplate with two

socket head cap screws (#24) using LOCTITE #243

thread locker sealant and torque the cap screws to 30

ft.-lbs.

Be careful to use a small amount of thread

locker to avoid dripping it into the helix pin carrier

bearings at installation.

23. Slide the input gear (#10) toward the pulley side of

the input shaft (#16). The gears should not be

meshing at this time.

Refer to LOWER SHAFT ASSEMBLY, page 30.

24. Install the ball bearings (#3) and the spacer washer

(#7) onto the shift shaft (#10) and secure with the e-

clip (#5).

25. Press the shift shaft and ball bearing assembly into

the helix pin carrier (#9) and secure with the internal

retaining ring (#8).

- 15-

Summary of Contents for 2900280

Page 10: ...6...

Page 31: ...4 15 10 3 5 9 8 7 11 19 18 14 6 2 0 21 22 13 16 17 1 22 2 12 Montage arbre inf rieur 26...

Page 35: ...16 6 15 7 12 10 5 3 14 1 8 13 11 9 2 4 Boitier de commande 30...

Page 42: ...NOTES 37...

Page 43: ...NOTES 38...

Page 52: ...6...

Page 73: ...4 15 10 3 5 9 8 7 11 19 18 14 6 2 0 21 22 13 16 17 1 22 2 12 Montage arbre inf rieur 26...

Page 77: ...16 6 15 7 12 10 5 3 14 1 8 13 11 9 2 4 Boitier de commande 30...

Page 84: ...NOTES 37...

Page 85: ...NOTES 38...

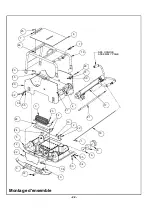

Page 108: ...22 Montage d ensemble 6 1 66 0 3...

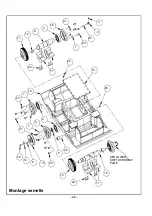

Page 110: ...24 6 2 5 6 7 66 0 3 Montage semelle...

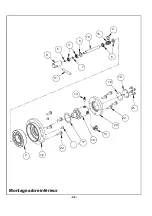

Page 112: ...26 Montage arbre inf rieur...

Page 114: ...28 Handle Assembly...

Page 116: ...30 Boitier de commande...

Page 118: ...32 6 0 1 1 21 6 5 48 5 0 6 06 1 21 3 Gasoline Engine Assembly...

Page 120: ...34 Diesel Engine Assembly...

Page 123: ...37 NOTES...

Page 124: ...38 NOTES...