- 9 -

S

ERVICE

Assembly and disassembly should be performed by a

service technician who has been factory trained on MBW

equipment. The unit should be clean and free of debris.

Pressure washing before disassembly is recommended.

• Prior to assembly, wash all parts in a suitable cleaner or

solvent.

• Check moving parts for wear and failure. Refer to the

Replacement section in this manual for tolerance and

replacement cycles.

• All shafts and housings should be oiled prior to pressing

bearings. Also, ensure that the bearings are pressed

square and are seated properly.

• All bearings, seals, o-rings and gaskets should be

replaced when rebuilding gearbox.

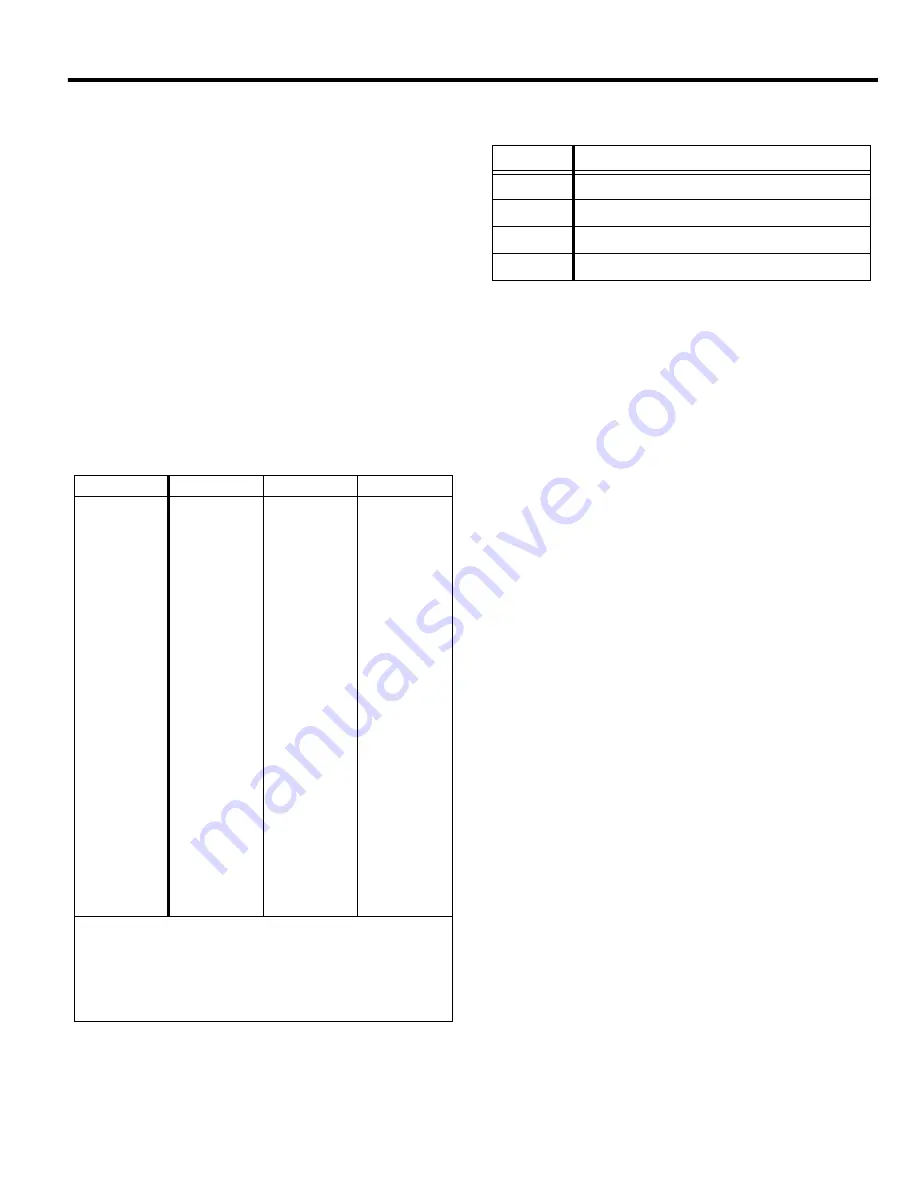

Torque Chart

Service Tools

Gearbox Disassembly

Refer to Gearbox Assembly, page 14.

1.

Remove the handle, belt guard & drive assembly

(page 18), engine & guard ring (page 20).

2.

Loosen the square head set screw (page 16, #20)

until the gearbox housing can be lifted off the spider

assembly.

3.

Flip the gearbox housing (#7) over and set it on the

four guard ring pads.

4.

Remove the yoke arm (#9) by removing one of the

retaining rings (#6), holding the pivot rod (#12) and

sliding the rod out of the holes.

5.

Remove the two flange bolts (#24) and the two flat

head screws (#25) that hold the cover (#8) to the

gearbox housing (#7).

6.

Remove the cover and discard the shims (#11) and

the o-ring (#5).

7.

Pull out the shaft (#14) with the bearings (#3) and the

worm gear (#13) and drain oil out of gearbox.

8.

Press bearing (#3) and worm gear (#13) off long side

of shaft (#14).

9.

Remove key (#15) and retaining ring (#2) from shaft.

10. Press remaining bearing (#3) off of shaft.

11. Remove the four flange bolts (#23) and the bearing

cap (#20). Discard the shim gasket (#10) and the

o-ring (#17).

12. Remove the worm shaft (#19) and the bearings (#22).

13. Remove the retaining cap (#21) and discard the shim

gasket (#10) and the o-ring (#17).

Gearbox Assembly

Refer to Gearbox Assembly, page 14.

1.

Lightly oil the shaft (#14). Install the key (#15) and

the retaining ring (#2) onto the shaft.

2.

With the retaining ring end of the shaft down, press

the worm gear (#13) onto the shaft. Make sure the

SIZE

GRADE 2

GRADE 5

GRADE 8

1/4-20

49 in

•

lbs

76 in

•

lbs

9 ft

•

lbs

1/4-28

56 in

•

lbs

87 in

•

lbs

10 ft

•

lbs

5/16-18

8 ft

•

lbs

13 ft

•

lbs

18 ft

•

lbs

5/16-24

9 ft

•

lbs

14 ft

•

lbs

20 ft

•

lbs

3/8-16

15 ft

•

lbs

23 ft

•

lbs

33 ft

•

lbs

3/8-24

17 ft

•

lbs

26 ft

•

lbs

37 ft

•

lbs

7/16-14

24 ft

•

lbs

37 ft

•

lbs

52 ft

•

lbs

7/16-20

27 ft

•

lbs

41 ft

•

lbs

58 ft

•

lbs

1/2-13

37 ft

•

lbs

57 ft

•

lbs

80 ft

•

lbs

1/2-20

41 ft

•

lbs

64 ft

•

lbs

90 ft

•

lbs

9/16-12

53 ft

•

lbs

82 ft

•

lbs

115 ft

•

lbs

5/8-11

73 ft

•

lbs

112 ft

•

lbs

159 ft

•

lbs

5/8-18

83 ft

•

lbs

112 ft

•

lbs

180 ft

•

lbs

3/4-16

144 ft

•

lbs

200 ft

•

lbs

315 ft

•

lbs

1-8

188 ft

•

lbs

483 ft

•

lbs

682 ft

•

lbs

1-14

210 ft

•

lbs

541 ft

•

lbs

764 ft

•

lbs

1-1/2-6

652 ft

•

lbs

1462 ft

•

lbs

2371 ft

•

lbs

M 6

3 ft

•

lbs

4 ft

•

lbs

7 ft

•

lbs

M 8

6 ft

•

lbs

10 ft

•

lbs

18 ft

•

lbs

M 10

10 ft

•

lbs

20 ft

•

lbs

30 ft

•

lbs

CONVERSIONS

in

•

lbs x 0.083 = ft

•

lbs

ft

•

lbs x 12 = in

•

lbs

ft

•

lbs x 0.1383 = kg

•

m

ft

•

lbs x 1.3558 = N

•

m

Part No.

Description

07276

Adjustment Tool, Tilt Arm Parallelism

07277

Adjustment Tool, Tilt Arm Height Gage

07279

Installation Tool, Spider Bushing (#06459)

16421

Bearing Spool Tool (Constant Force)

Summary of Contents for F36/4

Page 17: ...14 Gearbox Assembly...

Page 19: ...16 Spider Assembly...

Page 21: ...18 127 86 21 21 25 52 1 Drive Assembly...

Page 23: ...20 7 58 7 58 Guard Assembly...

Page 25: ...22 Handle Assembly...