Installation and use

9

MCK 3000

3.2 Sensor installation

The

MCK 3000 Area Control

can be equipped with 3 types of sensors:

•

speed sensor (always present);

•

mechanical counting sensor (for NON self-levelling combine harvesters, tractors,

etc.);

•

reflection seed sensor (for self-levelling combine harvesters).

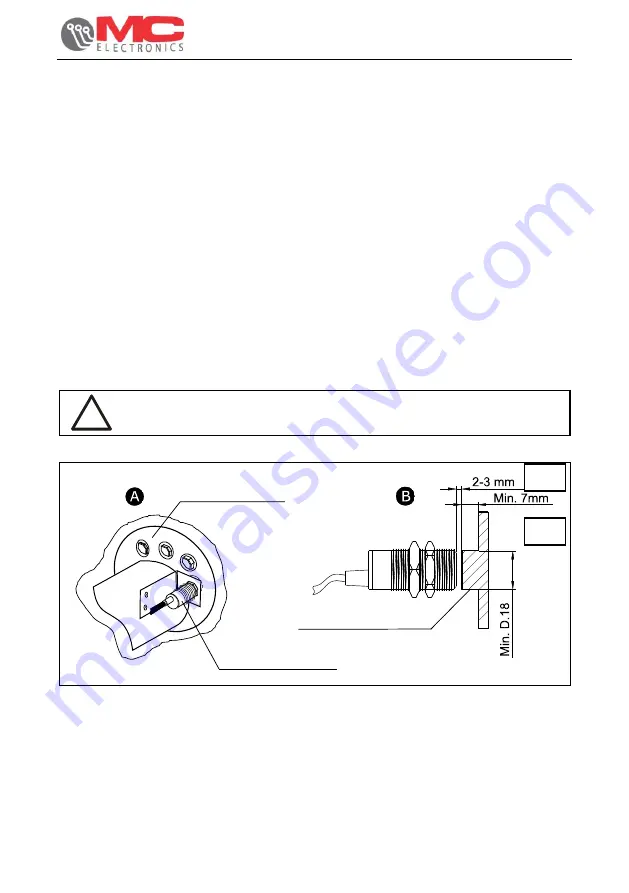

3.2.1 Speed sensor installation

You can install the speed sensor anywhere there is mechanical movement, on the

wheel (front or rear) of the agricultural machine/vehicle or by creating a metal

reference protruding by at least 7 mm ( Figure 4 ref. B2). We recommend installing

the speed sensor inside the wheel and placing the sensor head opposite the rim bolts

(Figure 4

– ref. A and B).

Set the gap between the sensor and the bolts at about 2/3 mm (Figure 4

– ref. B1).

Firmly fix the sensor bracket (supplied) to a secure part of the machine. Fix the

sensor to the bracket with the nut and the lock nut.

!

Warning

The sensor cable should be covered with a rubber sheath.

Figure 4. How to install the speed sensor.

Inner side of wheel

Speed sensor

Metal reference

B2

B1