Installation and use

41

SEEDER MAT MCK 2500 SX

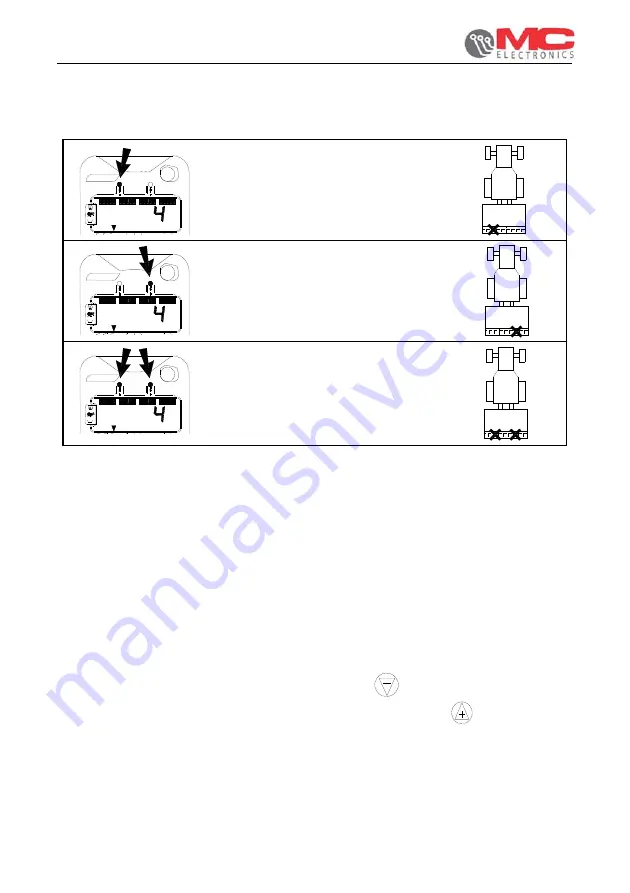

During operation, when one of the “path” is reached which requires closing

on right row, left rows or both, on the computer panel, the LED relevant to

the rows that were closed will turn on, according to the following scheme:

MCK 2500 SX

ON

OFF

If this LED lights up: only the left

rows of the seeder close.

MCK 2500 SX

ON

OFF

If this Led lights up: only the left rows

of the seeder close.

MCK 2500 SX

ON

OFF

If both LEDs light up:

Both the left and right rows of the

seeder close.

NOTE

: all the alarms (product reserve, turbine RPM, and distributor) are active only

when working and if the start/stop key has been pressed (the working condition is

always signaled by the flashing of a part of the bars on the display). When the

start/stop key is pressed again, the bars on the display remains permanently lit, and

the alarms are interrupted (also see settings for “S” and “M” constants – pg. 31).

When working, the computer controls the state of the magnetic sensor on

the row tracer disk arm, moving from one path/swath to the next each time

the row tracer disk is raised or lowered. According to the programmed

number of “paths” parameter (see paragraph 5.5.1 – pg. 27), the computer

will carry out the closing of rows for the seeder, in order to trace the paths

for the next swath of the sprayer.

If a wrong maneuver is performed with the row tracer disk arm, and the

monitor moves to the next path/swath, the computer can be brought back to

the previous swath by simply pressing the

key once. It is also possible

to bring the computer to the next swath by pressing the

key

.