10

MAINTENANCE

Daily Maintenance

Grease shaft bearings thoroughly.

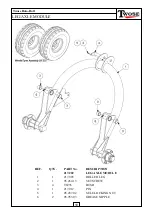

Check wheel nuts for tightness

– 185 lbs/ft.

(250Nm).

Weekly Maintenance

Grease pivot points thoroughly.

Check all nuts and bolts for tightness.

Check tyres for damage and ensure they are correctly inflated to 70psi

(5.2Bar).

Check and grease wheel bearings.

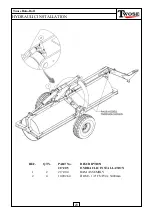

Inspect hoses for splits or damage.

Inspect hydraulics rams for signs of leaks or damage.

Laying Up & Pre-Storage Maintenance

Ram rods should be closed or greased to protect chrome surfaces.

Drain water ballast from rollers.

Clean machine thoroughly and inspect for damaged or worn components;

arrange for spares

or repair if required to ensure the machine is ready for next seasons work.

Lubricate the machine fully and store in a dry undercover location.

Summary of Contents for ROTA-ROLL Twose Series

Page 1: ...Twose Series ROTA ROLL 3 6M Folding Roller Operator Parts Manual Publication 686 May 2016...

Page 3: ......

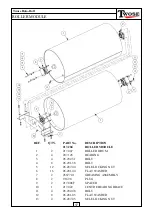

Page 20: ...12 ROTA ROLL 3 6M Folding Roller Parts Manual...

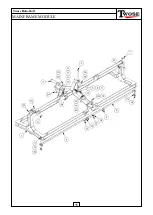

Page 23: ...15 Twose Rota Roll MAINFRAME MODULE...

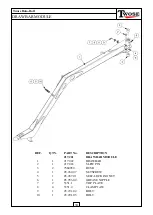

Page 27: ...19 Twose Rota Roll LIFT ANGLE MODULE...

Page 33: ...25...