Technical specifications

247

9

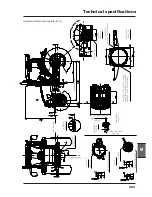

Hydraulic circuit

Two stage hydraulic gear pump powered directly by the

gears of the timing system with 40 micron double paper

filter on the intake.

The two pump stages supply:

1st Stage: delivery 29,9 l/min at a 2200 RPM engine rate.

20 micron paper filter on the delivery.

Supplies: - The power steering circuit, max. operating

pressure 150 +/- 5 bar.

- The 17-18 bar low pressure circuit including

Xtrashift, the four-wheel drive, the hydraulic

Power Take-Off, the hydraulic brake of the Po-

wer Take-Off, the differential lock and T-tronic

(if installed).

- The oil cooling circuit, max. pressure 5 bar.

- The lubricating circuit of the gearbox, max.

pressure 1.5 bar.

2nd Stage: flow rate 60 l/min at 2200 RPM engine rate. -

Supplies: - The hydraulic trailer brake, max. operating

pressure 130 +/- 10 bar.

- The auxiliary control valves (max. 4), max.

operating pressure 180 +/- 5 bar.

- The hydraulic power lift, max. operating pres-

sure 180 +/- 5 bar.

Electronically controlled power lift

Draft control, position control, “Intermix” combined draft

and position control, and float mode.

Monitoring system ...........................................Electronic

Type of control ......................................Electro-hydraulic

Electronic plant, sensors

and electro-distributor ..........................................BOSCH

Draft control by means of 2 sensors fitted to the lower

links of the three point linkage.

Operating voltage rating .......................................12 Volt

Three-point linkage

[4.2.g]

Class 2 three-point linkage with side stabilizers to limit

implement swing.

Adjuster crank on RH vertical link rod. Optional hydraulic

adjuster jack.

Adjuster crank of LH link rod with two positions at the

lower end: one fixed and the other sliding.

Lower links with quick hitch mechanisms on request.

Top link with quick hitch mechanism, optional hydraulic

adjuster jack.

Three point linkage powered by one single-acting hydrau-

lic cylinder, diameter 100 mm, coupled to two auxiliary

cylinders mounted as standard.

Max. lifting capacity at ends of articulated rods in hori-

zontal position

:

• with 2 auxiliary cylinders, diam. 60 mm (on request)

(max. pressure 200 bar) ................................5000 Kg.

Auxiliary control valves

Open center auxiliary control valves with rapid “Push-Pull”

attachments.

The auxiliary control valves use the power lift pump, thus

the max. operating pressure is 180 bar.

NOTE: Ask your Dealer for complete configurations of

auxiliary control valves.

Summary of Contents for X60 Series

Page 39: ...39 Controls Cab 3 Section 3 Controls Cab...

Page 61: ...61 Instruments and Programming 4 Section 4 Instruments and Programming...

Page 90: ...90 Instruments and Programming This page has been left blank intentionally...

Page 91: ...91 Operation 5 Section 5 Operation...

Page 151: ...149 Tyres Wheels Ballasting 6 Section 6 Tyres Wheels Ballasting...

Page 168: ...166 Tyres Wheels Ballasting This page has been left blank intentionally...

Page 169: ...167 Maintenance 7 Section 7 Maintenance...

Page 229: ...Electrical system 227 8 Section 8 Electrical system...

Page 242: ...Electrical system 240 Page left intentionally blankf...

Page 256: ...Technical specifications 254 This page has been left blank intentionally...

Page 262: ...260 Alphabetical index...