14

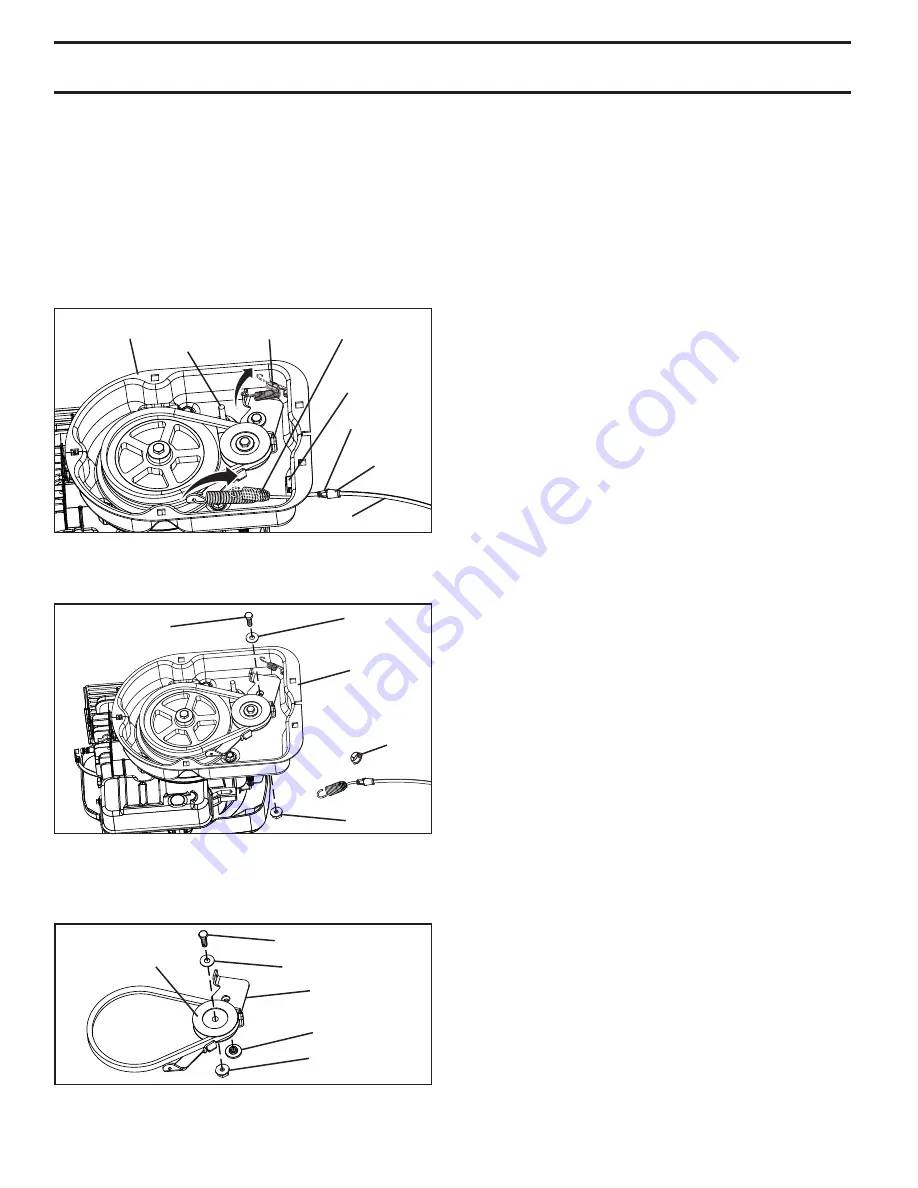

Fig. 20

Fig. 21

Fig. 22

ENGINE

TO AD JUST CARBURETOR

The carburetor has been preset at the factory and ad just ment

should not be necessary. However, engine per for mance

can be affected by dif fer enc es in fuel, tem per a ture, al ti tude

or load. If the carburetor does need ad just ment, contact

your nearest authorized service center/de part ment

IMPORTANT:

NEVER TAMPER WITH THE ENGINE GOVER-

NOR, WHICH IS FACTORY SET FOR PROPER ENGINE SPEED.

OVER SPEED ING THE ENGINE ABOVE THE FACTORY HIGH

SPEED SETTING CAN BE DANGEROUS. IF YOU THINK THE

ENGINE-GOVERNED HIGH SPEED NEEDS ADJUSTING,

CONTACT YOUR NEAREST AUTHORIZED SERVICE CENTER/

DEPARTMENT, WHICH HAS THE PROPER EQUIP MENT AND

EXPERIENCE TO MAKE ANY NEC ES SARY ADJUSTMENTS.

TO REPLACE V-BELT (SEE Fig. 20 - 22)

• Clutch housing/engine assembly must be removed to

service belt. See "TO REMOVE CLUTCH HOUSINGI-

ENGINE ASSEMBLY" in this section of manual.

• Using pliers, remove cable spring and return spring

from pivot bracket.

• Remove plastic snap-in plug from clutch housing.

•

Using pliers, depress conduit fitting tabs and pull conduit

fitting through hole in clutch housing.

• Pull cable spring and cable through snap-in plug hole

in clutch housing.

• Remove bolt, washer, and lock nut attaching idler

bracket to clutch housing.

•

Remove bolt, washer, and lock nut attaching idler pulley

to idler bracket. Remove bushing from between idler

bracket and clutch housing.

•

Replace belt and reinstall pulley, idler bracket, conduit

fitting, springs, and hardware in reverse order.

•

Reinstall clutch housing/engine assembly, making sure

belt is inside belt guide stud.

•

Check tine operation. See "To Check Tine Operation"

in this section of manual.

CABLE

SNAP-IN

PLUG

CONDUIT

FITTING

TABS

RETURN

SPRING

CABLE

SPRING

CLUTCH

HOUSING

BELT

GUIDE

STUD

LOCK NUT

WASHER

BOLT

CLUTCH

HOUSING

SNAP-IN

PLUG

LOCK NUT

BOLT

WASHER

IDLER BRACKET

IDLER PULLEY

BUSHING

SERVICE AND ADJUSTMENTS