14

SERVICE AND ADJUSTMENTS

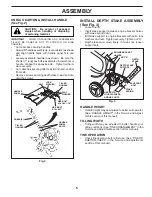

b

elts_10

Fig. 22

FORWARD MOTION

(INSIDE) V-BELT

ENGINE PULLEY

REVERSE

IDLER ARM

REVERSE

IDLER PULLEY

IDLER

ARM PIN

Fig. 21

FORWARD

IDLER PULLEY

REVERSE

IDLER

PULLEY

ENGINE PUL-

LEY

FRONT VIEW REFERENCE

REVERSE (OUTSIDE) V-BELT

FORWARD MOTION (INSIDE) V-BELT

TRANS MIS SION

PUL LEY

BELT GUARD

BOLT

BELT

GUIDE

REVERSE

IDLER PULLEY

IDLER

ARM PIN

ENGINE

PULLEY

REVERSE (OUTSIDE)

V-BELT

FORWARD IDLER

PUL LEY

REVERSE

IDLER PULLEY

ENGINE PULLEY

BELT GUIDE

TRANS MIS SION

PULLEY

BELT GUIDE

FORWARD

IDLER PULLEY

ENGINE

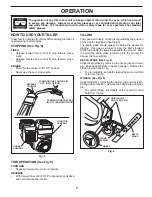

TO AD JUST CARBURETOR

The carburetor has been preset at the factory and ad just ment

should not be necessary. However, engine per for mance

can be affected by dif fer enc es in fuel, tem per a ture, al ti tude

or load. If the carburetor does need ad just ment, contact

your nearest authorized service center/de part ment

IMPORTANT:

NEVER TAMPER WITH THE ENGINE GOVERNOR,

WHICH IS FACTORY SET FOR PROPER ENGINE SPEED.

OVER SPEED ING THE ENGINE ABOVE THE FACTORY HIGH

SPEED SETTING CAN BE DANGEROUS. IF YOU THINK THE

ENGINE-GOVERNED HIGH SPEED NEEDS ADJUSTING,

CONTACT YOUR NEAREST AUTHORIZED SERVICE CENTER/

DEPARTMENT, WHICH HAS THE PROPER EQUIP MENT AND

EXPERIENCE TO MAKE ANY NEC ES SARY ADJUSTMENTS.

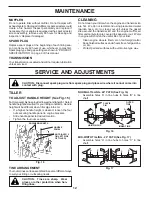

BELT REMOVAL

• Remove reverse idler pulley from idler arm.

• Remove reverse (outside) V-belt.

•

Remove forward (inside) V-belt from transmission pul ley

first and then from engine pulley.

BELT REPLACEMENT

•

Install new forward (inside) V-belt to engine pulley first

then to transmission pulley. Be sure belt is positioned

on inside groove of both pulleys, inside all belt guides

and rests on idler pulley.

•

Before installing reverse (outside) V-belt, turn belt “in side

out”. Twist so wide, flat surface of belt is to inside.

•

Wrap V-belt around reverse idler pulley and re as semble

idler to idler arm. Tighten securely. Be sure belt is

between reverse idler pulley and idler arm pin.

•

Install belt to outside groove of transmission pulley. Be

sure belt is inside all belt guides and rests on outside

groove of engine pulley.

CHECK TINE OPERATION

• See “TINE OPERATION CHECK” in this section of

manual.

REPLACE BELT GUARD

Summary of Contents for 532 43 36-95

Page 1: ...532 43 36 95 MHDF800 Operator s Manual...

Page 17: ...17 SERVICE NOTES...