12

S

As you move forward to the next area to cut,

be sure to maintain your balance and footing.

Cut using the 2

o’clock to 4 o’clock

position of the

blade

2 o’clock

4 o’clock

RECOMMENDED CUTTING POSITION

WARNING:

The operator or others

must not try to clear away cut material with the

engine running or the blade turning to avoid

serious injury. Stop engine and blade before

removing materials wrapped around blade or

shaft.

MAINTENANCE

The life span of the machine can be reduced

and the risk of accidents can increase if ma-

chine maintenance is not carried out correctly

and if service and/or repairs are not carried

out professionally. If you need further infor-

mation, please contact your nearest autho-

rised service dealer.

WARNING:

Disconnect the spark

plug before performing maintenance except

for carburetor adjustments.

CHECK FOR LOOSE

FASTENERS AND PARTS

S

Spark Plug Boot

S

Air Filter

S

Housing Screws

S

Handlebar Screws

S

Combination Shield

CHECK FOR DAMAGED OR

WORN PARTS

Contact an authorized service dealer for re-

placement of damaged or worn parts.

S

ON/STOP (I/0) Switch -- Ensure ON/STOP

(I/0) switch functions properly by moving

the switch to the STOP (0) position. Make

sure engine stops; then restart engine and

continue.

S

Fuel Tank -- Discontinue use of unit if fuel

tank shows signs of damage or leaks.

S

Combination Shield -- Discontinue use of

unit if shield is damaged.

INSPECT AND CLEAN UNIT AND

LABELS

S

After each use, inspect complete unit for

loose or damaged parts. Clean the unit and

labels using a damp cloth with a mild deter-

gent.

S

Wipe off unit with a clean dry cloth.

CLEAN AIR FILTER

A dirty air filter decreases engine perform-

ance and increases fuel consumption and

harmful emissions. Always clean after every

5 hours of operation.

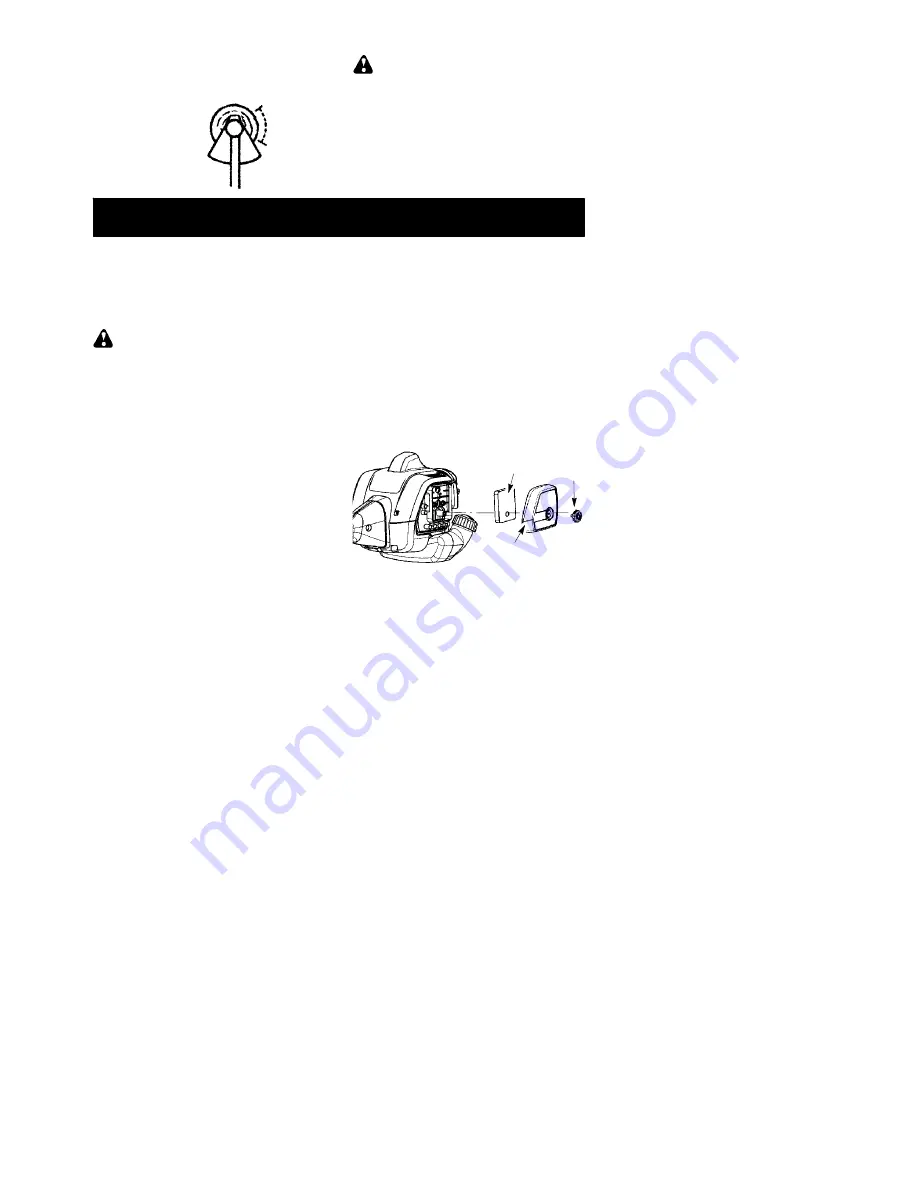

1. Clean the cover and the area around it to

keep dirt from falling into the carburetor

chamber when the cover is removed.

2. Remove parts as illustrated.

NOTE:

Do not clean filter in petrol or other

flammable solvent to avoid creating a fire haz-

ard or producing harmful evaporative emis-

sions.

3. Wash the filter in soap and water.

4. Allow filter to dry.

5. Replace parts.

Air Filter

Air Filter Cover

Knob

REPLACE SPARK PLUG

Replace the spark plug each year to ensure

the engine starts easier and runs better. Set

spark plug gap at 0,6 mm. Ignition timing is

fixed and nonadjustable.

1. Twist, then pull off spark plug boot.

2. Remove spark plug from cylinder and dis-

card.

3. Replace with Champion RCJ-6Y spark

plug and tighten securely with a 19 mm

socket wrench.

4. Reinstall the spark plug boot.