6000XL Series Service and Installation Manual

For customer service, call (800) 733-8829, (800) 733-8821, Fax (888) 779-2040, www.delfield.com

8

Delfield

™

®

Operation

Electronic Temperature Control

Operation:

The electronic temperature control constantly monitors box

temperature as well as evaporator coil temperature to maintain

consistent product temperatures. The control also sends

temperature readings to the digital temperature display. The

control circuits continually self-check and if an error occurs,

the digital display will switch from temperature read-out to

error read-out, i.e. E 1. Even when an error is displayed, the

refrigeration and controls system should continue to function,

however not at optimal performance. Whenever the display has

an error read-out, Delfield Service should be contacted.

At initial start-up or anytime power is disconnected, then

reconnected to the unit, the control will delay all operations for

a short time (up to 10 minutes.) While in this delay period, the

control initializes the control parameters and confirms that the

temperature sensors and circuits are operational. The digital

temperature display will not display temperature OR errors until

the self-check is complete and the control has switched on the

evaporator fan motor, compressor and condenser fan motor.

IMPORTANT NOTE REGARDING FREEZERS:

After initializing,

the control will immediately enter a DEFROST mode and the

display will read DEF. The compressor and condenser fan as

well as the evaporator fan will remain off until initialization

defrost is complete. This initial defrost cycle may take up to

15 minutes to complete, at which time the freezing cycle will

begin. The display will continue to read DEF for an additional

30 minutes before displaying temperature.

Temperature Alarm:

The alarm will flash “HI” or “LO” 90 minutes after the unit has

reached its alarm temperature point or after any power interruption

if the temperature is above or below the alarm set points.

Refrigerators are factory set at mid-range to maintain about 38ºF

(3ºC) box temperature. The high refrigerator temperature point

is 50°F (10°C). The low refrigerator temperature point is 25°F

(-4°C). Freezers are factory set at mid-range to maintain about 3ºF

(-18ºC) box temperature. The high freezer temperature point is

20°F (-7°C). Freezers do not have a low temperature point.

Refrigerator:

The control is located in the control box in the top of the

refrigerator behind the removable louvered panel on the left

side. It is factory set at mid-range to maintain about 38˚F (3˚C)

box temperature. To adjust for colder temperatures,

turn the knob clockwise. For warmer temperatures, turn the

knob counter-clockwise. Turn the knob fully counter-clockwise

to turn the refrigeration system off. Never turn the knob more

than 1 dial number and always allow 8 hours for temperature

stabilization before making any additional adjustments.

Freezer:

The control is located in the control box in the top of the

refrigerator behind the removable louvered panel on the left

side. It is factory set at mid-range to maintain about -3˚F

(-18˚C) box temperature. To adjust for colder temperatures,

turn the knob clockwise. For warmer temperatures, turn the

knob counter-clockwise. Turn the knob fully counter-clockwise

to turn the refrigeration system off. Never turn the knob more

than 1 dial number and always allow 8 hours for temperature

stabilization before making any additional adjustments.

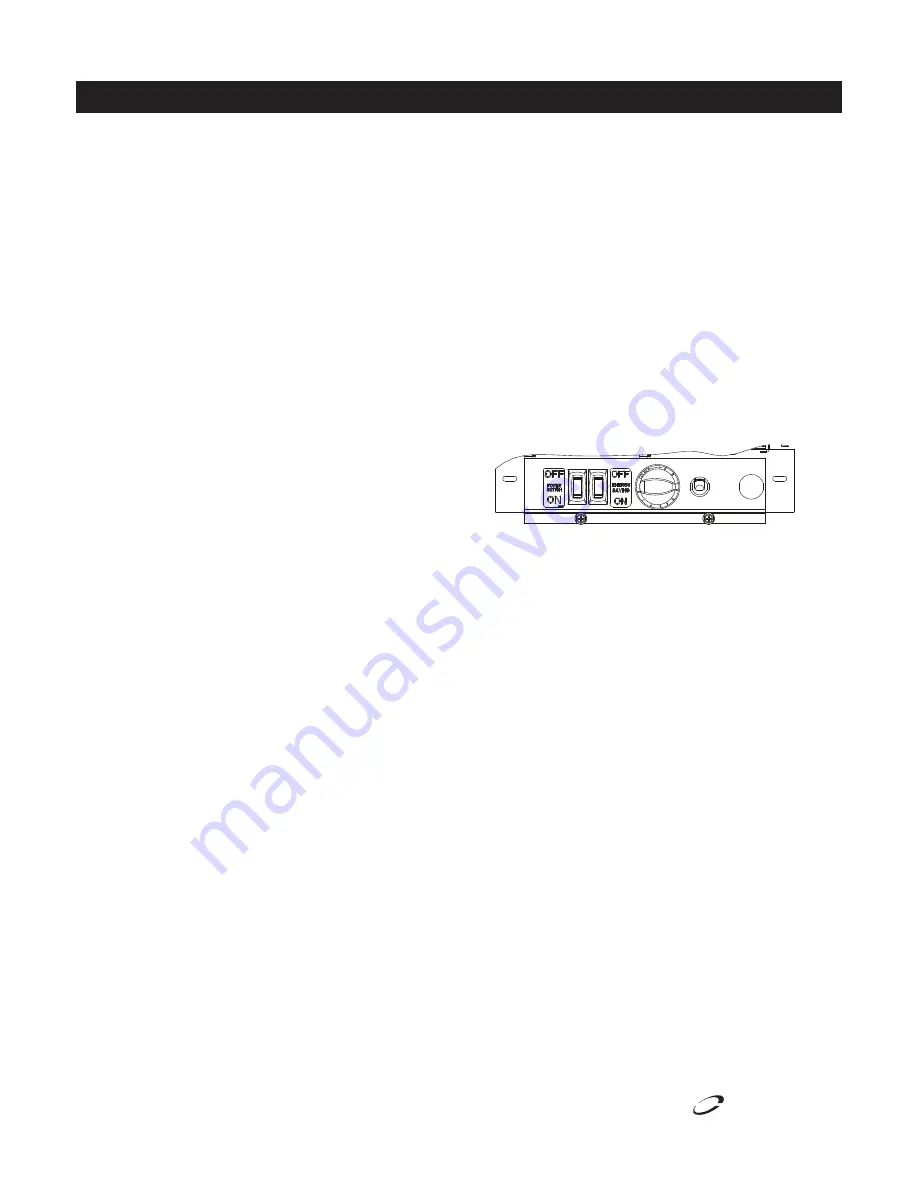

Power Switch

Select units are equipped with a power disconnect switch

located next to the energy saver switch and thermostat control

knob. Switch must be in the “on” position for the unit to

operate. On freezers, if the switch is turned off, then returned to

the on position, the unit will enter a defrost cycle and the display

will read “Def.”

Energy Saver Switch

The energy saver switch is a rocker switch located next to

the thermostat knob that controls the amount of heat applied

to the door perimeter. The normal operating position for this

switch is the ON position, providing the least heat. If excessive

condensation is observed on the door opening, press the

energy saver switch to the OFF position, to increase the amount

of heat (red portion of the rocker switch will be visible).

Refrigeration & Defrost Cycle

Refrigerator:

Whenever the refrigerator is plugged in, and the control

has completed initializing, the digital thermostat will display

box temperature. The temperature control will cycle the

compressor, evaporator fan motor and condenser fan motor to

maintain box temperature at the control setting. See evaporator

fan matrix for more information.

Refrigerator Defrost

The temperature control also monitors the evaporator

temperature and will turn off the compressor and condenser

fan motor when needed to allow accumulated frost on the

evaporator to clear. During this defrost cycle, the digital

temperature display will read dEF. After the defrost cycle is

complete, the temperature control will return to a normal

cooling cycle, but the display will continue to read dEF until the

evaporator returns to normal cooling temperatures (up to 30

minutes).