3

S

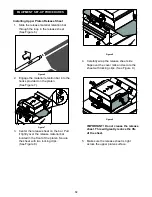

The grill must be placed on a level

surface.

S

To ensure thorough cleaning, the grill

must be pulled away from the wall.

When returning the grill to its original

position, use extreme caution to

smoothly and slowly roll the grill

backward into place.

Failure to follow these instructions may cause

the grill to tip and can result in severe

equipment damage or personal injury.

NOTICE

all warning labels that have

been attached to the grill to further point out

safety precautions to the operator.

HAZARD COMMUNICATION STANDARD

(HCS) - The procedure(s) in this manual

include the use of chemical products.

These chemical products will be

highlighted with bold faced letters followed

by the abbreviation (HCS) in the text

portion of the procedure. See the Hazard

Communication Standard (HCS) manual for

the appropriate Material Safety Data

Sheet(s) (MSDS).

This piece of equipment is made in America

and has American sizes on hardware. All

metric conversions are approximate and vary

in size.

NOISE LEVEL:

Airborne noise emission does

not exceed 70 dB(A) when measured at a

distance of 1.0 meter from the surface of the

machine and at a height of 1.6 meters from

the floor.

These instructions are valid only if the country

code symbol appears on the appliance. If the

symbol does not appear on the appliance,

refer to the technical instructions which give

the necessary instructions for adapting the

appliance to the utilization conditions of that

country.

If the crossed out wheeled bin symbol

is affixed to this unit, it signifies that this unit is

compliant with the EU Directives as well as

other similar end of life legislation in effect

after August 13, 2005. Therefore, it must be

collected separately after its use is completed,

and cannot be disposed as unsorted municipal

waste.

The user is responsible for returning the

product to the appropriate collection facility, as

specified by your local code.

For additional information regarding applicable

local laws, please contact the municipal facility

and/or local distributor.

Summary of Contents for C836

Page 2: ......

Page 7: ...5 150209 C836 Exploded View Figure 1 2015 Carrier Commercial Refrigeration Inc ...

Page 9: ...7 150209 C838 Exploded View Figure 2 2015 Carrier Commercial Refrigeration Inc ...

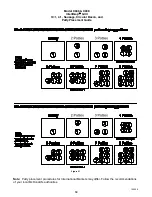

Page 64: ...Rev 2 15 C836 C838 WIRING DIAGRAM 083305 75 ...

Page 65: ......

Page 66: ......

Page 67: ......

Page 68: ...073530 M ...