Automated Beverage System

Closing/Sanitation Procedures

© 2004-2018 The Coca-Cola Company, Cornelius and

McDonald’s Corporation. All Rights Reserved.

41

CAUTION:

!

Do not use sharp objects, metal devices or abrasives on the ice hopper, top cover, ice chute or

agitator disc, repairable damage may result. Do NOT use solvent or other cleaning agents as

they may attack the plastic material.

CAUTION:

!

The ABS equipment or any of its components may not be cleaned using water jet cleaning equip-

ment. Water jet cleaning equipment must not be used within a 3 foot radius of the ABS unit.

Daily Cleaning/Sanitizing Tasks

At close, the following tasks should be per-

formed:

• Put in manual mode (do not shut off main power).

• Remove and clean the conveyor, and cup rest.

Clean drip tray and exterior surfaces.

• Pour warm

(NOT HOT)

water down the drip tray

drain.

• Check for water deflector. If missing, use the

spare located behind the lid holder panel.

• Reinstall cup rest and conveyor.

• Remove and clean the valve nozzle and diffuser.

• Wipe down and clean the A.B.S. unit with san-

itizing solution.

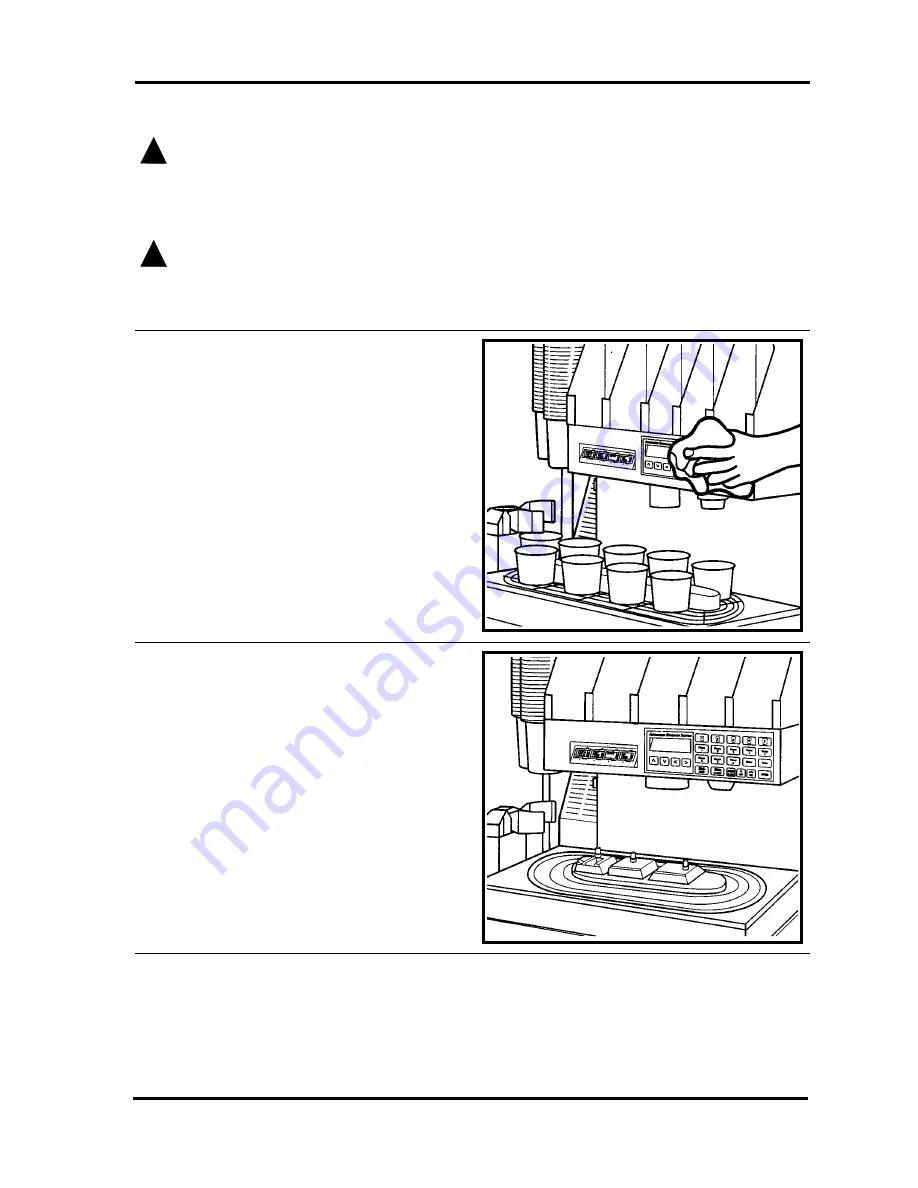

Remove Conveyor & Cup Rest

Remove the conveyor by removing the 3

thumb screws holding it in place. Remove the

cup rest by lifting it up and removing it. Wash

the conveyor, conveyor cover, and the cup

rest in warm soapy water then rinse with

clean potable water.

Summary of Contents for CORNELIUS AUTOMATED BEVERAGE SYSTEM

Page 2: ......