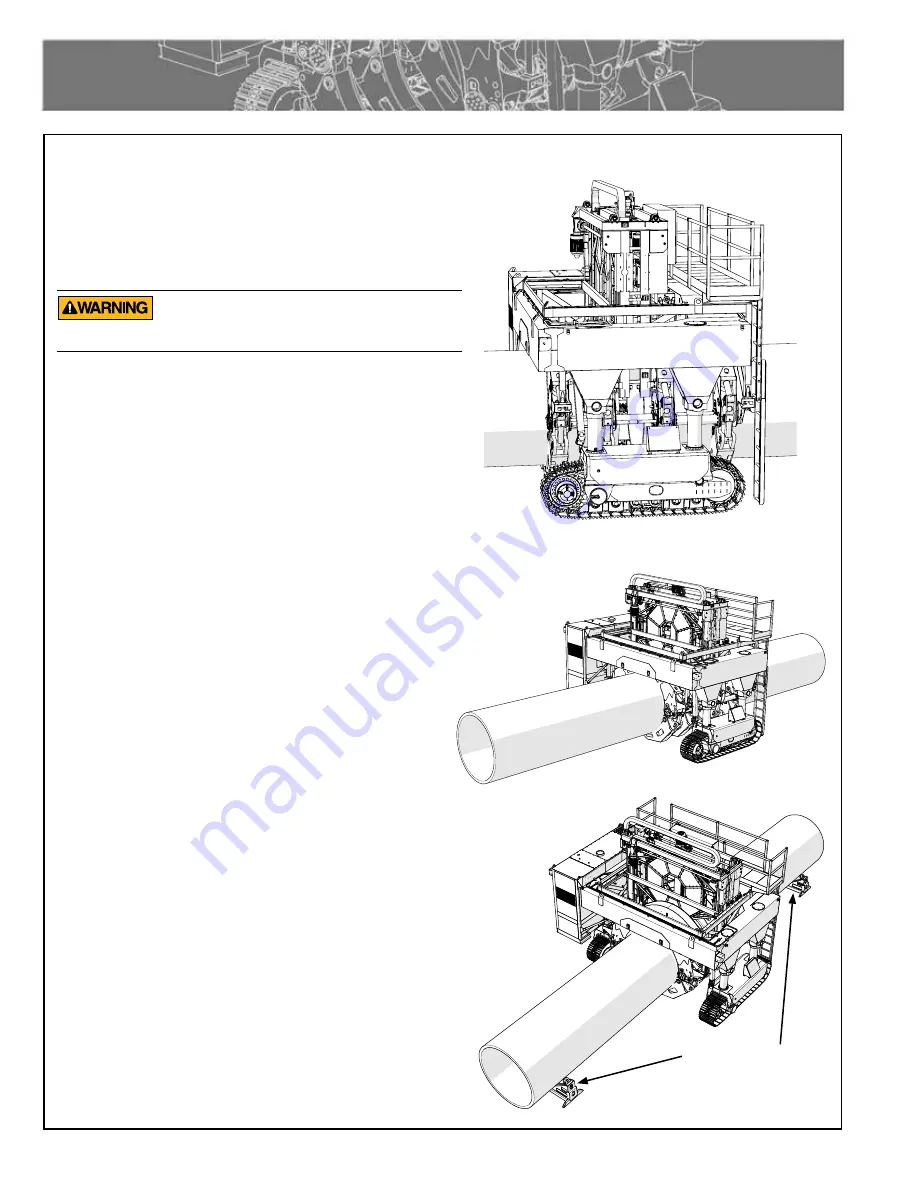

Load Pipe

The Talon 2000 fusion machine loads pipe into the machine by

using the carriage quarter jaws to pull the pipe up into the carriage

upper jaws.

The fusion machine can clamp onto the middle of the pipe allowing

the machine to move pipe into position on the job-site for fusion.

Do not position yourself under supported or

raised pipe. Pipe is heavy and could result in

serious injury or death.

Keep persons that are not involved in handling pipe away from

handling operations. Keep away from the pipe when the pipe and

handling equipment are in motion. When in motion, all persons

involved in handling pipe should be able to see all other persons

at all times. If any handling person is not in sight, immediately

stop moving equipment and pipe and locate that person. Do not

continue until all persons are accounted for and in sight.

Å

Position pipe support stands at each end of the machine to

support and align pipe.

Å

Use the Machine Controls screen to load the pipe into jaws

of the carriage.

Allow 3 to 4 inches of pipe protruding into the fusion zone to

allow proper facing.

NOTICE:

Do not exceed 4" of pipe protruding.

Å

Ensure the pipe is clamped securely in the jaws of the

carriage.

It is recommended that the pipe is always held securely by either

being clamped in the fusion machine jaws or other means.

TX05023-05-03-16

4 - 2

Operation

¡ADVERTENCIA!

Pipe Supports

CD0

13

12-0

4-1

5-1

6

CD0

140

4-0

4-1

5-1

6

CD0

1405-0

4-1

5-1

6