Remove Facer

Swing the facer out to the storage position.

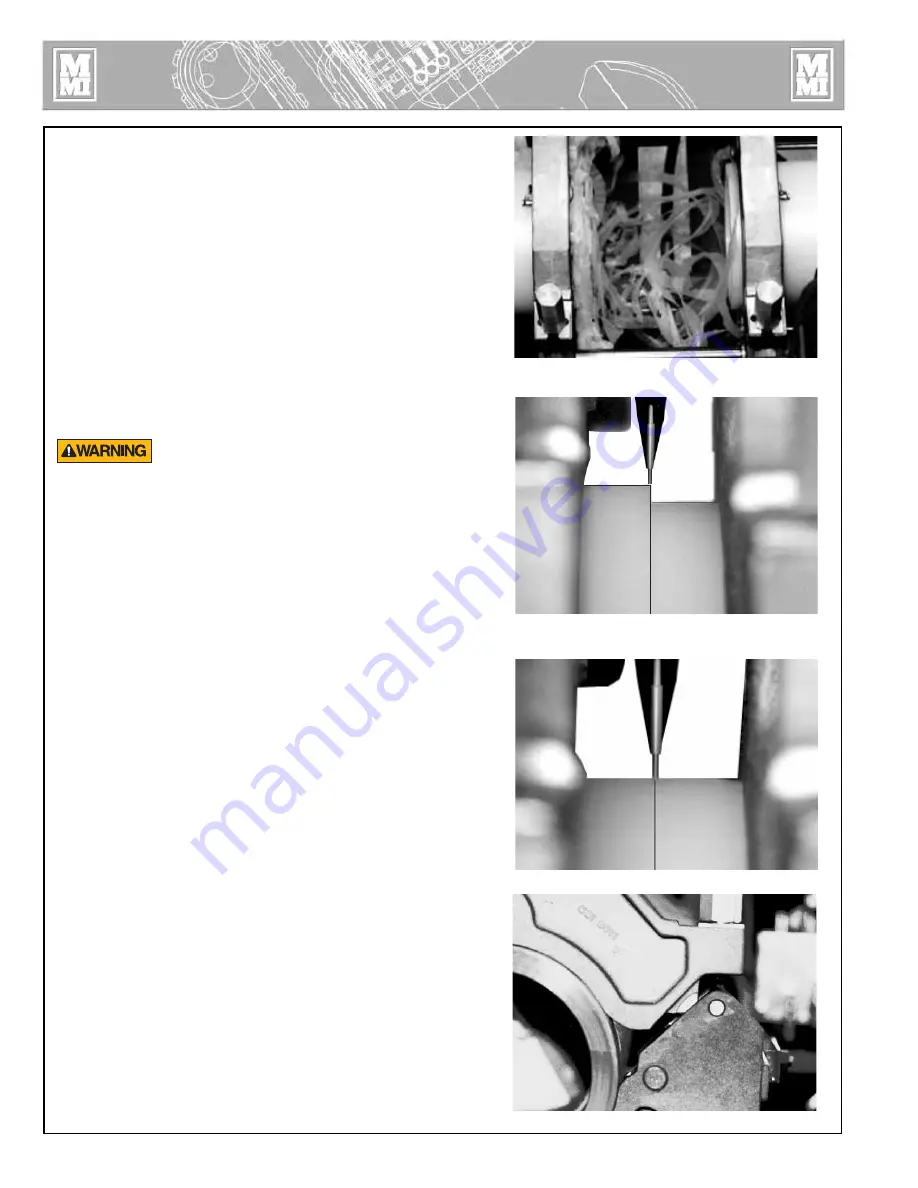

Remove chips from pipe ends.

Do not touch faced pipe ends.

Inspect both pipe ends for complete face off. If the face off is

incomplete, return to

Loading Pipe into Machine

.

Move the carriage to the left until ends of pipe butt together.

Check pipe joint for proper alignment.

Do not use finger to check for hi/lo

(misalignment). The unit is under pressure, and

slippage could result in crushed fingers. Always

keep hands clear of the jaw area.

If pipe is not lined up, tighten the high side jaw to bring into

alignment.

IMPORTANT:

Always tighten the side that is higher, never loosen

the low side.

When the pipe is properly aligned tighten outside clamps to

insure against slippage.

Ensure there is no unacceptable gap between the pipe ends.

If there is an unacceptable gap, return to

Loading Pipe into

Machine

.

NOTICE:

When clamping, do not over-tighten the clamp knobs

because machine damage can result. Check to see if there is

space between the upper and lower jaws. If the two jaws are

touching, do not continue to tighten.

Bring the pipe ends together under fusion pressure to check

for slippage. If slippage occurs, return to

Loading Pipe into

Machine

.

TX01873-11-15-00

Operation

PH00362-9-14-94

3 - 5

PH00366-9-12-94

PH00357-9-12-94

PH00323-9-25-93

Summary of Contents for TracStar 28

Page 63: ......