Summary of Contents for HDL-1000 Series

Page 32: ...APPENDIX B 32 HDL 1024 through HDL 1038 HARROW CART PARTS DIAGRAM...

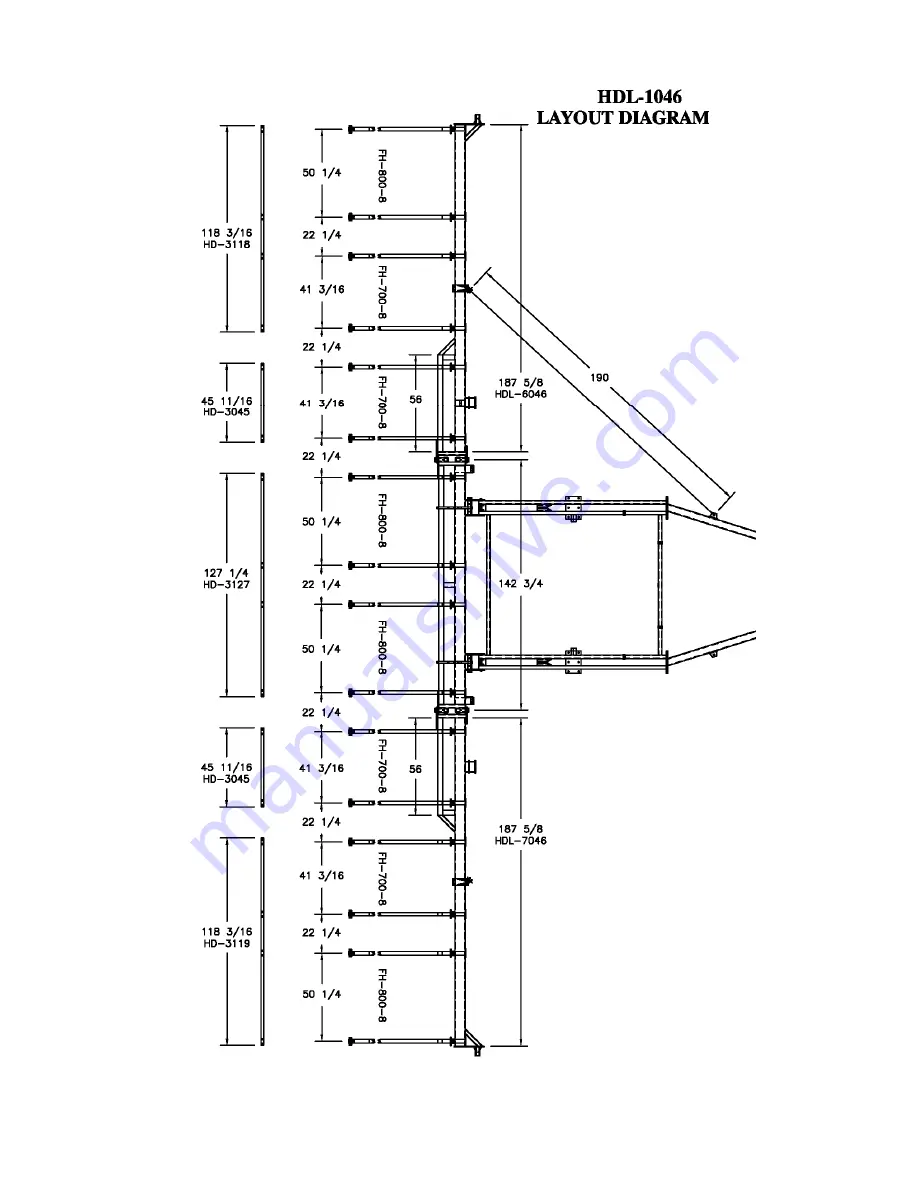

Page 35: ...APPENDIX B 35 HDL 1040 THROUGH HDL 1050 HARROW CART PARTS DIAGRAM...

Page 38: ...APPENDIX B 38 HDL 1052 THROUGH HDL 1060 HARROW CART PARTS DIAGRAM...

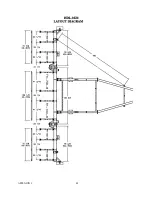

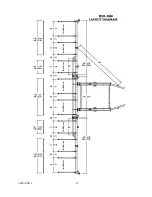

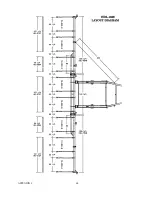

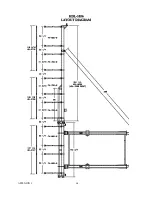

Page 48: ...APPENDIX C 48...

Page 49: ...APPENDIX C 49...

Page 50: ...APPENDIX C 50...

Page 51: ...APPENDIX C 51...

Page 52: ...APPENDIX C 52...

Page 53: ...APPENDIX C 53...

Page 54: ...APPENDIX C 54...

Page 55: ...APPENDIX C 55...

Page 56: ...APPENDIX C 56...

Page 57: ...APPENDIX C 57...

Page 58: ...APPENDIX C 58...

Page 59: ...APPENDIX C 59...

Page 60: ...APPENDIX C 60...

Page 61: ...APPENDIX C 61...

Page 62: ...APPENDIX C 62...

Page 63: ...APPENDIX C 63...

Page 64: ...APPENDIX C 64...

Page 65: ...APPENDIX C 65...

Page 66: ...Notes...

Page 68: ......

Page 69: ......