McHale

995 L+T

Square Bale Wrapper

28

There are 3 settings for the width between the roller cradle centres:

.

6.2 Plastic Film Requirements

It is of the utmost importance that top quality plastic film is used for wrapping bales.

Always follow plastic film manufacturer’s recommendations on the storage and use of

the film.

It is recommended that a minimum of 4

layers of film are applied to the bale. If the

material being wrapped is of a hard or stemmy nature it may be necessary to apply 6

or 8

layers to ensure a good airtight package.

The operator needs to ensure that the bale is correctly wrapped. It is good practice to

periodically check the bales after being wrapped for any torn, split or punctured plastic

film. If the stubble in a particular field has a tendency to puncture the plastic film, it is

strongly advised to wrap the bales at the stack, where there may be more control over

ground conditions.

The plastic film must be applied to the centre of the bale. If it is too low or too high adjust

the dispenser height as appropriate. See “Dispenser height” on page 58.

To determine the number of table rotations required to wrap a bale, carry out the

following procedure:

1.

Count the number of table revolutions to cover the bale completely with plastic

film

2.

Add 1 to this number

3.

Multiply this resultant figure by 2 (for 4 film layers) or 3 (for 6 film layers)

Example:

Number of rotations to cover the bale: 7

Number of rotations to apply 4 layers of film to the bale: (7+1) x 2 = 16

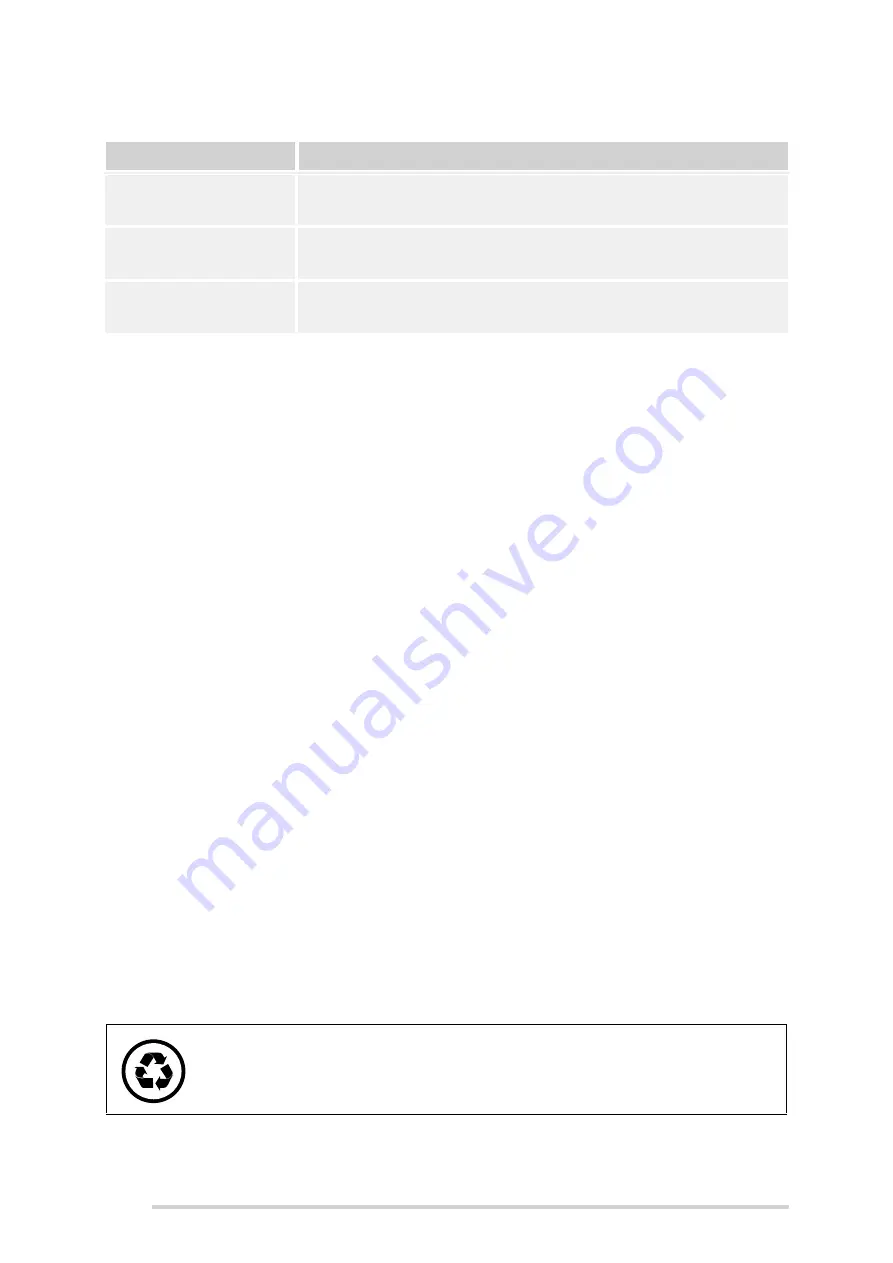

Cradle drive setting:

Typical Bale Size:

810 mm

600 x 900 mm, or where the shortest side of the bale is within

a 600-650 mm range

850 mm

700 x 800 mm or where the shortest side of the bale is within

a 650-750 mm range

900 mm

800 x 900 mm or where the shortest side of the bale is within

a 750-800 mm range

ENVIRONMENT: Recycling of film roll

Respect the environment! Never throw away or burn the waste film and

the core tube. Always take waste materials to a recycling centre.