3

IMPORTANTS

NOTES

Recomendações importantes

Name:

METALÚRGICA CONVENÇÃO DE ITU LTDA.

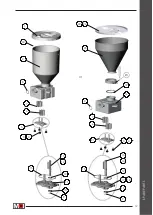

Address:

Zip code:

1028, Sete Quedas Avenue

13.313 - 006

Bairro:

City/ State:

Vila Padre Bento

Itu – SP

CNPJ:

State Enrollment:

49.563.117/0001 - 72

387.024.638.117

Phone:

+55 011 40137223

SAFETY INSTRUCTIONS

Carefully read the Maintenance and Operation Manual, as for all the indicated warnings on the

equipment before operating it. Failure to follow these instructions and notices may result in serious

injuries to the operator.

1. The equipment must be installed in locations where use and maintenance are restricted to trained

and/or qualified people;

2. Do not install the equipment in locations exposed to water jet. Do not immerse its bottom in water

or other liquid, nor rinse it with running water, unless advised by a specific instruction.

3. The MCI equipment shall be installed with suitable electrical grounding. Failure to this electrical

grounding may cause electrical damages to the equipment, such as the electronic board burning.

For your safety, ask for a qualified electrician to check the conditions of the power grid of the

equipment installation site.

4. This equipment shall not be operated by people with physical or mental limitation nor children,

unless they are instructed for the use of the equipment and supervised by a responsible person for

their safety;

5. Take off rings, jewelry, watches and loose clothes. Keep your hair away from the moving parts of

the machine;

6. Never use accessories or parts from other manufacturers. Before switching on the device, be sure

that all the parts are correctly assembled;

7. Only operate the equipment if the safety protections are perfectly fitted. The protections shall only

be removed from the device when it is switched off;

8. Before connecting the device, be sure that the indicated voltage of the equipment is the same as

the socket. The voltage of this equipment is 115 V;

9. Do not use the device if the plug or the power cable are damaged;

10. Connect your equipment into a close and exclusive socket. Do not use extension cables or plug

adapters (T type). Arrange the equipment in a way that it does not interfere with its disconnection

from the power supply. Do not connect the equipment into damaged sockets;

11. The total shutdown occurs when the power plug is removed from the socket. In case of

abnormalities, remove the power plug from the socket;

12. Equipment for internal use. The equipment must be installed in a horizontal plane and has at least

0.25 m (10 in) widht and 0.40 m (16 in) lenght. It is ideal to have a complementary support area for

tools;

13. The operating temperature range is from 10 °C (50ºF)to 40 °C(104ºF);

14. Carefully follow the equipment cleaning and disassembly procedures shown in this manual;

15. A thorough reading of this manual and/or video visualization of the Pratic Desk allows the

operator to be capable of operating this equipment. Access the website:

www.minidesk.ind.br

MCI recommends the mandatory use of all safety devices.

Any modification in the equipment, changes or adjustments of the safety systems installed by MCI

may cause serious injuries to the physical integrity of the machine operator.

MCI is not responsible for any modification in the equipment. The machine's owner is considered

responsible for any changes.