Care

Point:

If there is a build up of CCM on the

internal diameter of the disc (1),

this is due to it having a higher

wear rate at the inner part of the

disc (1).

1.

This condition (C) should be matched by the

pad (2). Please note that this does not affect

the performance of the disc (1).

Care

Point:

Discs must be replaced if pad

wear has reached 100%.

If pads have reached 100% wear,

there is a high chance that the

back plate has come into contact

with the braking face (visible mark

will be present).

2.

Discs (1) must be replaced immediately if this

circumstance has occurred due to

contamination of the disc (1).

Care

Point:

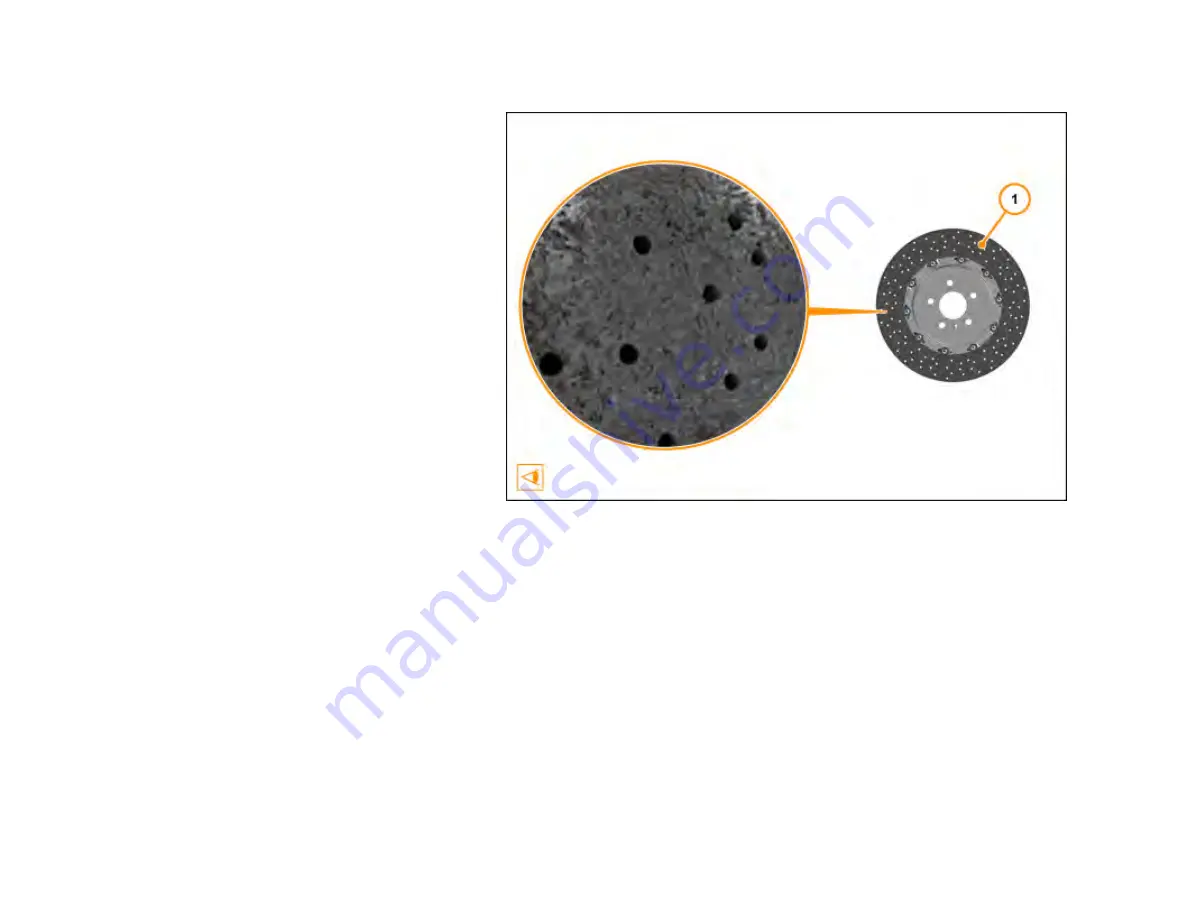

Any visual change to the braking

surface of the disc is caused when

the fibres within the CCM

experience a high level of thermal

input. This then causes the fibres

to oxidize, changing the surface

appearance. This condition mainly

occurs after extreme use, such as

racing.

The oxidisation level is calculated

by disc porosity and surface

roughness. Areas that are mainly

affected by the change in the

braking surface are an increase in

pad wear, decreased NVH, and a

decrease in disc performance.

If the level of oxidisation

experienced is very high, the disc

must be replaced. See below for

examples of the different levels of

oxidisation experienced:

3.

Disc surface (1)

–

Immediately after bedding

–

Do not renew.

4.

Disc surface (1)

–

200 km racing on track

–

Do

not renew.

5.

Disc surface (1)

–

500 km racing on track

–

Do

not renew.

6.

Disc surface (1)

–

1000 km hard racing on

track

–

Check disc weight.

7.

Disc surface (1)

–

1500-2000 km racing on

track

–

Renew disc (end of disc life).

Care

Point:

Tool used when assessing damage must be a precision gauge with a tolerance of 0.1mm.

Care

Point:

If disc is damaged outside of specified figures along the edge of the braking surface, disc must be renewed.

Care

Point:

Any damage on the edge of the braking surface will not affect the disc weight due to the material density.

Checking CCM disc

–

Damage control specifications

29

Summary of Contents for MP4-12C

Page 1: ......

Page 35: ...5 Disc Cross Drilled Hole Chip on disc Do not renew disc 1 34 ...

Page 52: ...2 Detach union nut 2 M10 17 Nm 3 Loosen nut 3 4 Remove front brake hose 4 51 ...

Page 69: ...2 Detach union nut 2 M10 17 Nm 3 Loosen nut 3 4 Remove rear brake hose 4 68 ...

Page 98: ...Description Dimension Value Bolt Floor panel tunnel M6 x 16 10 Nm 97 ...

Page 104: ...1 Remove bolts 1 M6 x 20 4 Nm 2 Remove tyre spoilers 2 Remove front guide vanes 103 ...

Page 105: ...1 Remove screws 1 M6 x 16 6 Nm 2 Remove front guide vanes 2 Remove rear guide vanes 104 ...

Page 125: ...Description Dimension Value Track rod steering rack M14 30 Nm 124 ...

Page 194: ...4 Remove bolts 2 M6 x 20 8 Nm 5 Remove bolts 3 M6 x 16 8 Nm 193 ...

Page 195: ...5 Remove bolts 3 M6 x 16 8 Nm 6 Remove bolts 4 M6 x 16 8 Nm 194 ...

Page 196: ...6 Remove bolts 4 M6 x 16 8 Nm 7 Remove bodyside lower rear arrows 195 ...

Page 203: ...Description Dimension Value Clamp ISG to Throttle M6 5 Nm 202 ...