OM AGSB-5

13

Circuit Operating Mode

The circuits on the chiller can each be individually enable or disabled. Test mode on each

circuit can also be entered independent of the all other circuits. With the circuit switch on,

the circuit mode setpoint offers settings of either Enable or Disable. This simply allows the

circuit to be disabled through a keypad setting.

Cool Mode

When the chiller is in COOL mode, capacity of the compressor is adjusted to maintain

leaving water temperature at the Active LWT setpoint while balancing the load between

running circuits. Load balance offset, LWT error, and LWT slope are used to calculate a

change in slide position.

ICE Mode

Ice mode is designed to have the compressors run at full load until the LWT setpoint is

reached, then shut off until the next ice making cycle starts. ICE settings are made in the

unit controller.

In ICE mode, the compressor capacity is increased at the maximum rate continuously until

reaching the maximum slide position. Load balancing, LWT error, and LWT slope are

ignored. Low and high pressure events are disabled.

An adjustable Start-to-Start Ice Delay Timer will limit the frequency with which the chiller

may start in ICE mode. The timer starts when the first compressor starts while the unit is in

ICE mode. While this timer is active, the chiller cannot restart in ICE mode. The time

delay is user adjustable.

The Ice Delay Timer may be manually cleared to force a restart in ICE mode. A set point

specifically for clearing the ICE mode delay is available. In addition, cycling the power to

the controller will clear the Ice Delay Timer.

Circuit Test Mode

The circuit test mode allows manual testing of all controller outputs. Entering this mode

requires the following conditions.

•

Circuit Switch = OFF

•

Technician password active

•

Circuit Mode setpoint = TEST

A test menu can then be selected to allow activation of the outputs. It is possible to switch

each digital output ON or OFF and set the analog outputs to any value. Upon entering the

test mode, all outputs will always default to the OFF state. Upon leaving the test mode, all

outputs will automatically reset to the OFF state.

Compressors cannot be started in TEST mode.

Slide Position

Each compressor will estimate its slide load percentage from the present value of the slide

load indicator. The percentage is based on the 4-20mA signal from the slide load indicator

and varies somewhat by compressor size. A load percentage value of 0 corresponds to mA

Low signal; a percentage value of 100 corresponds to the mA High signal shown in Table 6.

This information is located on the View Cir Status (1) menu. It shows slide position and

slide target.

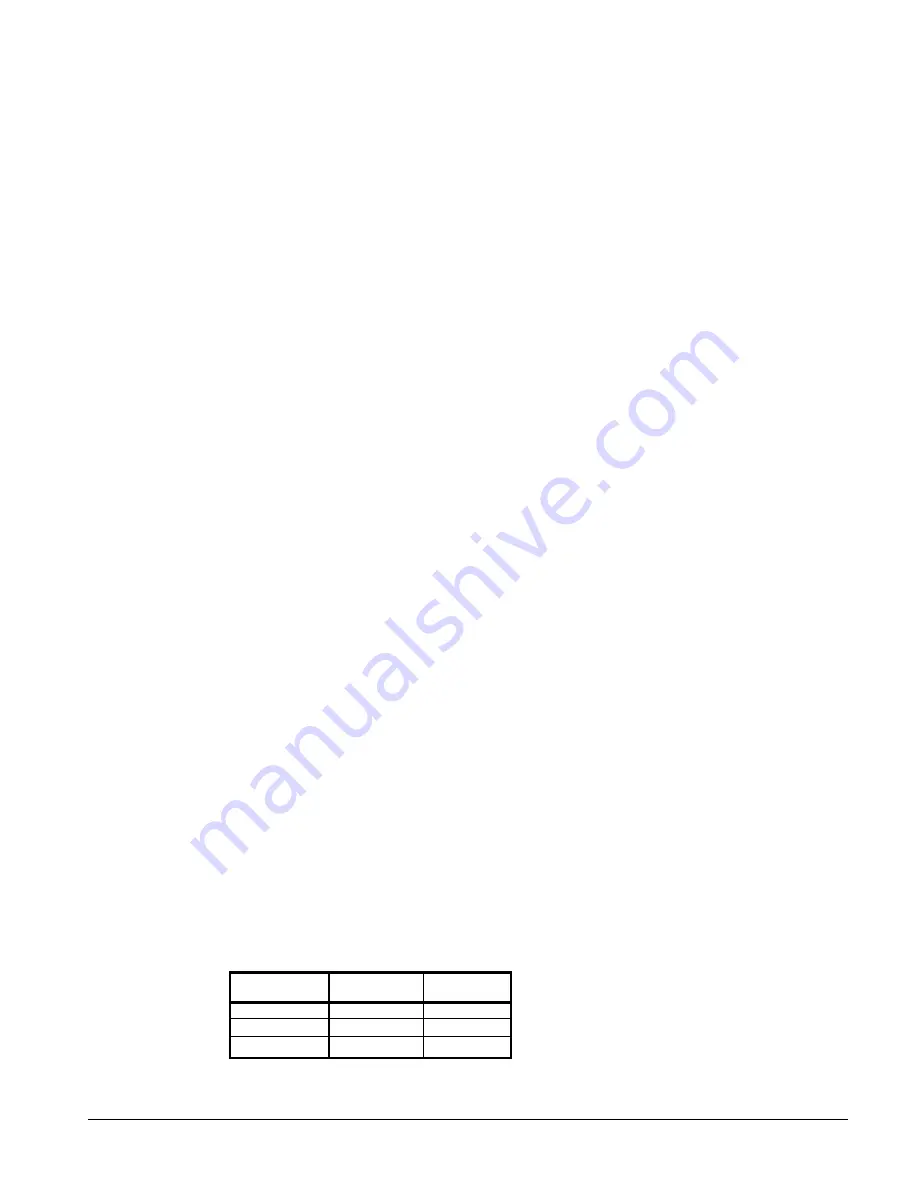

Table 6, Slide Valve Position

Compressor

Size

mA Low

mA High

205

4.94 14.6

220

4.62 17.0

235

4.32 19.4

NOTE

: See the Physical Data tables in IMM AGSB-60 for unit compressor sizes.

Summary of Contents for AGS 206A

Page 65: ......