Product Manual ALR2-3

ALR 110F – 150F

31

Restricted Air Flow

General

The clearances required for penalty-free operation of ALR air-cooled condensers are described in the

previous section. Inevitably there are situations where these clearances cannot be maintained due to

site restrictions such as units being too close together or a fence or wall restricting airflow, or both.

Fortunately the McQuay ALR chillers have several features that mitigate the penalties attributed to

restricted airflow.

•

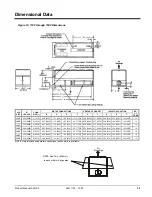

The condenser section is “U” shaped, as shown below. This allows inlet air for these coils to

come in from either side. A vertical coil and its adjacent horizontal coil are manifolded together to

serve one circuit.

•

The optional MicroTech control is proactive in response to “off-design conditions”. In the case

of single or compounded influences restricting airflow to the unit, the microprocessor will act to

keep the compressor(s) running (at reduced capacity) rather than allowing a shut-off on high

discharge pressure.

•

The optional MicroTech control can be programmed to sequence the compressors in the most

advantageous way. For example, in the diagram shown below, it might be desirable to program

circuit 2 to be the lag circuit (last circuit to reach full load) during periods of high ambient

temperatures.

Figure 12, Coil and Fan Arrangement

The following sections discuss the most common situations of condenser air restriction and give

capacity and power adjustment factors for each. It should be noted that in unusually severe

conditions the optional MicroTech controller would adjust the unit operation to remain online until a

safe condition is reached.