IM 685 / Page 3

General

This forced draft gas burner is specifically designed for use with the furnace on McQuay applied rooftop

heating and air conditioning units which are for outdoor installation only. Each model size has unique

burner head components to tailor the shape of the flame to each particular stainless steel combustion

chamber, to match the capacity requirement, and to offer a 20 to 1 turndown ratio. This is a forced

draft burner with a high pressure combustion air fan and will operate against pressure. This eliminates

the need for draft inducers, chimneys, draft hoods, barometric dampers, and Breidert caps.

Warranty Exclusion

Warranty is void if furnace is operated in the presence of chlorinated vapors, if the airflow through the

furnace is not in accordance with rating plate, or if the wiring or controls have been modified or

tampered with.

Units equipped with gas heating must not be operated in an atmosphere contaminated with

chemicals which will corrode the unit such as halogenated hydrocarbons, chlorine, cleaning

solvents, refrigerants, swimming pool exhaust, etc. Exposure to these compounds may cause severe

damage to the gas furnace and result in improper or dangerous operation. Operation of the gas

furnace in such a contaminated atmosphere constitutes product abuse and will void all warranty

coverage by the manufacturer. Questions regarding specific contaminants should be referred to

the appropriate local gas utility.

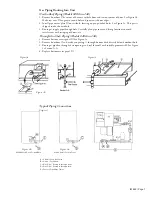

Ventilation and Flue Pipe Requirements

The McQuay applied rooftop unit is equipped with an outdoor air louver to supply adequate

combustion air. The unit also has a flue outlet assembly and requires no additional chimney, flue pipe,

Breidert cap, draft inducer, etc.

Factory Mounting

This burner and gas train has been installed and wired at the factory. See “Gas Piping.” Also note that

models 150 through 200 have the burner removed for shipment; see “Installation: Models 150-200.”

Factory Checkout

This complete heating plant was fired and tested at the factory. It was adjusted to the required capacity

and efficiency. Modulating air and gas linkages, pressure regulators, and stops were adjusted for proper

operation at all firing levels. The unit was fired through several complete start-up through shutoff

sequences to check operation. A check was made of the air switch, gas pressure switch, high limit

operation, and combustion characteristics including CO

2

and CO at several firing rates. If the burner

was specified for operation at higher altitudes, combustion air adjustments were compensated to result

in proper settings at the higher altitude. This checkout normally eliminates on-the-job start-up

problems; however, the equipment is subject to variable job conditions and shipping shocks can change

adjustments, cause damage, and loosen connections and fasteners. Therefore, it is necessary to go

through the complete start-up procedure even though the unit may appear to be operating properly.

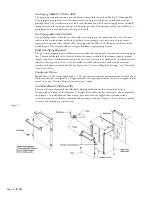

Installation

General

The installation of this equipment shall be in accordance with the regulations of authorities having

jurisdiction and all applicable codes. It is the responsibility of the installer to determine and follow the

applicable codes. Sheet metal parts, self-tapping screws, clips, and such items inherently have sharp

edges, and it is necessary that the installer exercise caution. This equipment is to be installed by an

experienced professional installation company that employs fully trained technicians.