IM 685 / Page 7

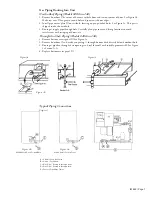

Gas Piping Routing Into Unit

On-the-Roof Piping (Models 020 thru 140)

1. Remove knockout

➀

at corner of burner vestibule door and saw out corner of door. See Figure 3b.

Make saw cuts

➁

tangent to round hole and square with door edges.

2. Install pipe corner plate

➂

on vestibule, locating on pre-punched holes. See Figure 3c. This part is

shipped inside the vestibule.

3. Route gas supply pipe through hole. Carefully plan pipe route and fitting locations to avoid

interference with swinging of doors, etc.

Through-the-Curb Piping (Models 020 thru 140)

1. Remove bottom access panel

➄

. See Figure 3c.

2. Remove knockout

√

and make an opening

≈

through bottom deck directly below knockout hole.

3. Route gas pipeline through these openings and seal them off with suitable grommets

∆

. See Figure

3a Section A-A.

4. Replace bottom access panel

➄

.

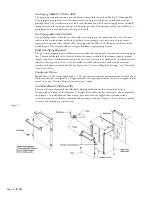

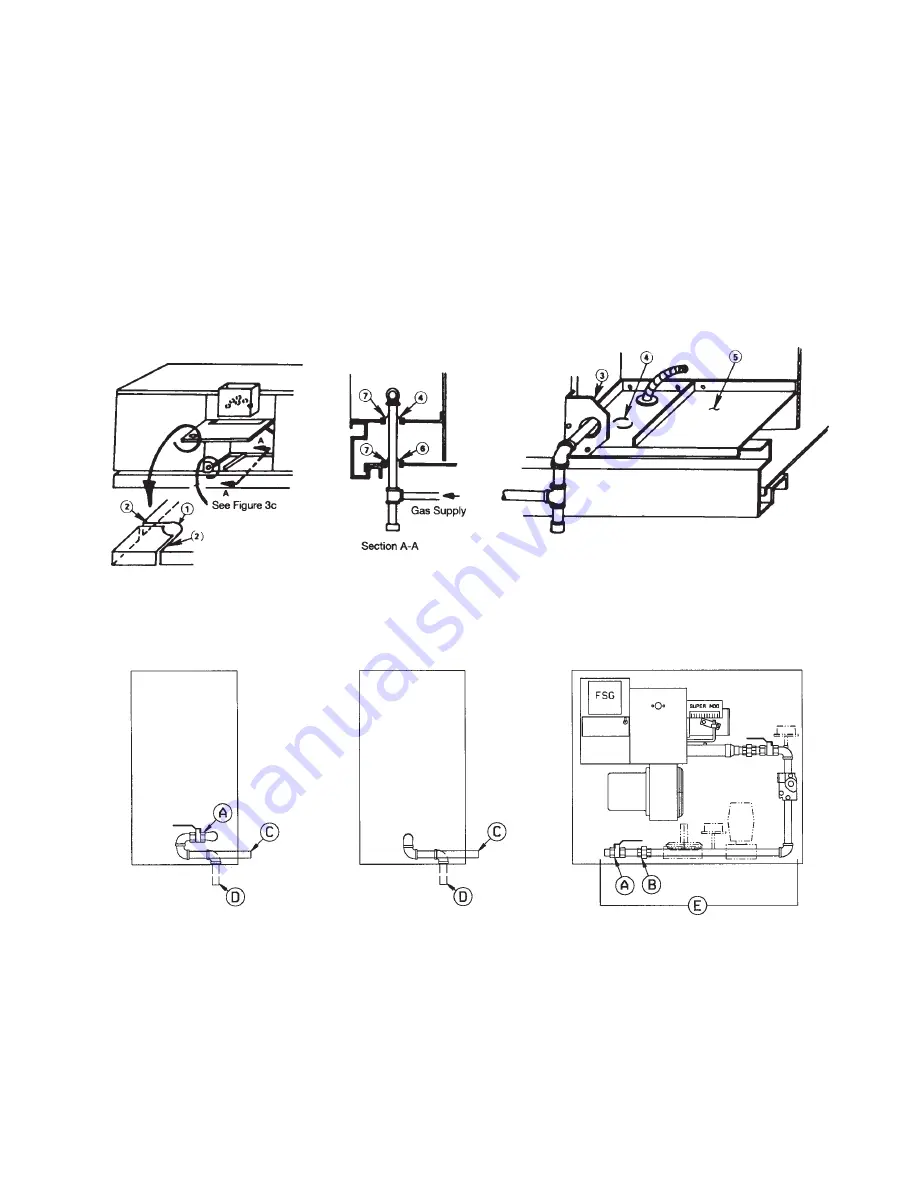

Typical Piping Connections

Figure 4

Figure 3a.

Figure 3c.

Figure 3b.

A = Shutoff Cock. ball valve

B = Union – Furnished.

C = Gas Pipe – Routed in through front.

D = Gas Pipe – Routed in through curb.

E = Factory Piped Gas Trains.

With Shutoff Cock Folded Back

With Shutoff Cock in Front

Figure 4b.

Figure 4a.