OPERATION

During full load operation, check the compressor oil

level. It should be near the center of the oil sight

glass during operation.

A.

B.

C.

D.

E.

Check the refrigerant charge frequently at the

moisture/liquid indicator. A steady clear glass of

liquid refrigerant indicates sufficient charge. A

green colored button in the center of the moisture

indicator indicates a dry system (should moisture

enter the system, the color will turn yellow). The

button was green before it left the factory and

should be green after a period of operation on

start-up. A filter-drier core change is recommended

for a persistent yellow indicator. (Page 26).

Check the temperature control thecmostat by ob-

serving operation at reduced loads. The thermostat

is factory set for 44F leaving chilled water tem-

perature when the entering temperature is 54F.

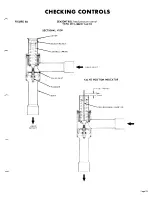

Refer to CHECKING CONTROLS section, Pages

20 and 21.

Checkvoltage and amperage of the compressor mo-

tor(s) and fan motors (see Field Wiring, Page 11).

When gauges ace furnished, close gauge ports by

back seating valves after readings ace checked.

This will prolong the gauge life and prevent refrig-

erant loss. Replace seal caps.

See SERVICE INFORMATION section, Pages 28

and 29 for Trouble Shooting Chart.

PERIODIC SERVICE

(At end of first week of operation and once a month

thereafter.)

A.

B.

C.

D.

A. Turn on water circulating pump.

Check

compressor oil level. Oil should cover ap-

proximately l/2 of the oil level glass. Copeland

Compressors ace furnished with oil fill plug on

the side of crankcase, should it be necessary to

add oil. (See Page 25, Paragraph E).

B. Turn pumpdown switches S3 and S4 to "auto” posi-

tion.

Check liquid sight glass ahead of expansion valve

for proper refrigerant charge.

C. Observe operation for several minutes, noting un-

usual sounds, or possible unusual cycling of

compressors.

EXTENDED SHUTDOWN

On belt driven units, check belt tension and ob-

serve condition of belts.

A. Close the liquid line shut-off valve.

Check the surface of the condenser coil for ob- B. Wait for the compressor to pump down until it

struction. If

necessary, flush with cold water,

shuts off.

brush off, or use vacuum cleaner.

E. Make general inspection of entice system for any

unusual sound or condition.

NORMAL REFRIGERANT CHARGE

The condenser coil has a built-in subcooler. For opti-

mum operation. the liquid sight glass in the liquid line

between the receiver and subcooler should be substan-

tially free of bubbles. A completely clear sight glass

indicates a possible overcharged system. No adverse

affect need be expected unless overcharge is suffici-

ent to affect an excessive head pressure caused by

appreciable liquid flooding of condenser portion of

coil. The minimum charge at which the unit will oper-

ate properly is with clear sight glass between the

filterdrier and thermostatic expansion valve.

WEEK END OR SHORT PERIOD SHUTDOWN

A.

B.

Turn pumpdown s w i t c h e s 5% a n d S 4 t o “ m a n ”

position. The compressor or compressors will con-

tinue to run for a short period, until the system

pumps down, and stops on opening of low pccssuce

control.

Turn off water circulating pump (Water circulating

pump is often left on the line as an assist against

damage by freezing of water).

WARNING:

Do not open main electrical discon-

n e c t switch as heater cable and crankcase heater

will be de-energized.

START UP FOLLOWING WEEK END SHUTDOWN

Page

18