CHECK

ING

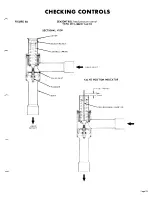

VALVE CHECKING AND SETTING

The SEASONTROL head pressure control valves are

factory set and checked to maintain a minimum head

pressure equivalent to 90F condensing. The valves

have a nominal 15 psig modulating range between fully

open and fully closed positions. Typical settings for

R-22 use is to have the valves modulate between 160

and 175 psig. This will maintain a nominal 90F con-

densing.

Referring to the sectional diagrams, it is to be

noted

that on pressure increase on the system, the pressure

will tend to compress the bellows and the valve stroke

will be up or toward the adjustment end of the valve.

This also applies to the 237 series valves. The 239

series, or liquid valves, open on pressure rise. The

valve travel is a nominal one tenth inch for all models.

As indicated in the diagrams, the adjustment of the

nut in a clockwise direction will increase the modu-

lating pressure point. A wide bladed screwdriver or

similar tool inserted into the nut slot may be used for

making the adjustment. Turning the adjustment nut

clockwise raises the control point.

The modulating pressure point and range may be

checked as follows:

A. Make up a “depth gauge” for inserting through the

adjusting nut opening and long enough to hit the

CONTROLS

B.

C.

D.

E.

bottom of the bellows section as indicated in the

diagrams. A piece of insulated wire, 8 to 12

gauge, is a simple and convenient method to make

a gauge. Insert a piece of the wire into the valve

as shown in diagrams. Trim off insulation, for

about one inch of the end to be inserted, and at a

point just above the top of the valve at the other

end. Hold the gauge down lightly against the bel-

lows and sight along the top of valve.

A high side gauge should be connected to a line

so it can be brought to the valve area while valve

observations are being made.

Start up the unit and note pressures at which valve

bellows rise. We assume that the pressure was low

enough at start up so that the bellows is in the

down position. The test may also be done in re-

verse by running the system upto a high head pres-

sure, stopping the unit, and making observations

at what pressure the valve changes position.

The valves should he set so that tho movement of

both valves is through the same pressure range.

Be sure system has sufficient refrigerant before

assuming valves are out of adjustment.

FIGURE 8A

SEASONTROL III

head pressure control

For operation at OF ambient.

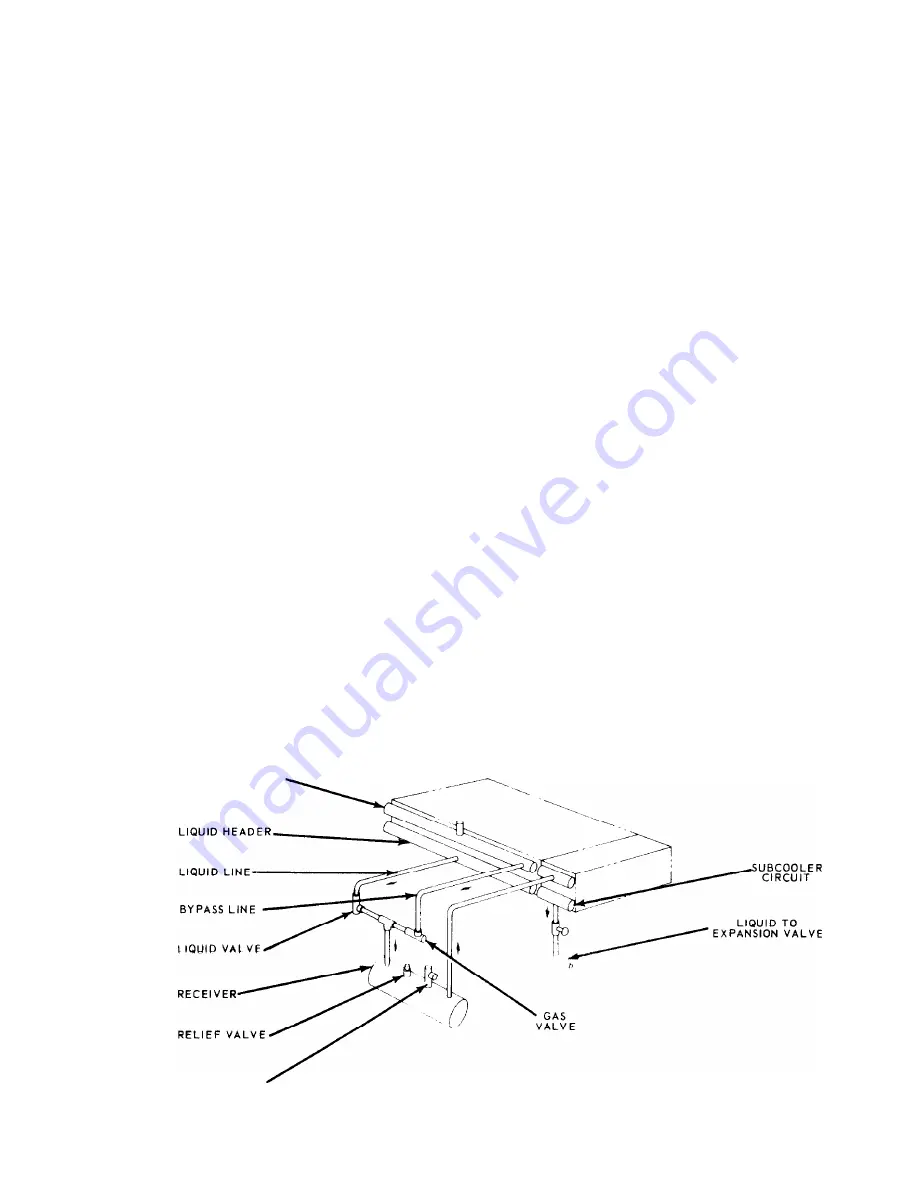

H O T G A 5 H E A D E R

P U R G E V A L V E

Page 22