FIGURE

1 0

A.

B.

C.

SYSTEM COMPONENTS

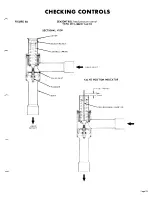

FIGURE 11

COMPRESSOR

D.

FS4-3 FLOW SWITCH

The reciprocating semi-hermetic compressor(s)

are complete with suction and discharge service

valves, integral force feed lubrication system, oil

sight glass, oil charging connection, crankcase

heater and initial oil charge.

T h e motor is of the hermetic induction type, 1750

rpm, gas cooled, with inherent

and/or supplementary overload

required. The standard unit is

the-line starting. Part winding

able as an option.

thermal protection

protection, where

wired for across-

starting is avail-

The compressor is pre-wired and ready to run.

Suction and discharge service valves are closed

during shipment and must be opened just prior to

start up. Gauge connections on suction and dis-

charge valves are closed when the valve stem is

back seated in the full open position. To increase

the life of any gauges supplied, the suction and

discharge valve should be back seated except when

readings are required. Always replace valve caps

with gaskets in place.

The safety

control

piping connection t o

t h e c o m -

pressor includes: the oil failure switch-high p r e s -

sure oil connection at the oil pump discharge; the

oil failure switch-low pressure connection at the

compressor crankcase; the high pressure safety

connection at the discharge manifold; and the low

pressure connection at the suction chamber on

the motor end of the compressor. Shut off valves

E.

F.

G.

VIEW FROM END OF COOLER

STRAIGHT PIPE

1

are never installed in these control lines.

The compressor is pre-charged with sufficient oil

for normal operation. In case oil is required. or if

unit requires additional oil after installation, the

compressor must be pumped down to near zero pres-

sure, valves closed, and oil charged through the

filler plug on the side of the compressor oil

sump.

The plug must be replaced with a sealer and leak

c h e c k e d

during operation. Precautions must b e

taken to prevent

air entry into crankcase or refrig-

erant system.

A compressor crankcase heater (energized by main

disconnect continually) is provided to minimize r e -

frigerant accumulation into the crankcase oil when

compressor is not in operation. Excessive refrig-

erant in the crankcase dilutes the oil, causing

excessive foaming, oil loss, and, in extreme cases,

bearing washout and possible failure. The heaters

are energized at all times. During prolonged shut-

down, when the electrical power may be shut off,

c l o s e the suction and discharge service valves to

prevent migration of the refrigerant to the oil and

reopen the valves just prior to start up. Also. allow

sufficient time for heater to boil refrigerant out of

c r a n k c a s e oil .

Except for minor repairs such as replacing a suc-

tion or discharge reed valve, the compressor is not

generally repaired in the field. Exchange comprcs-

sors are stocked in warehouses throughout the

country and the damaged compressor is turned in

for credit.

Page 25