SYSTEM COMPONENTS

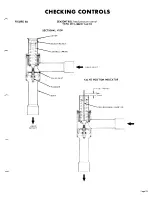

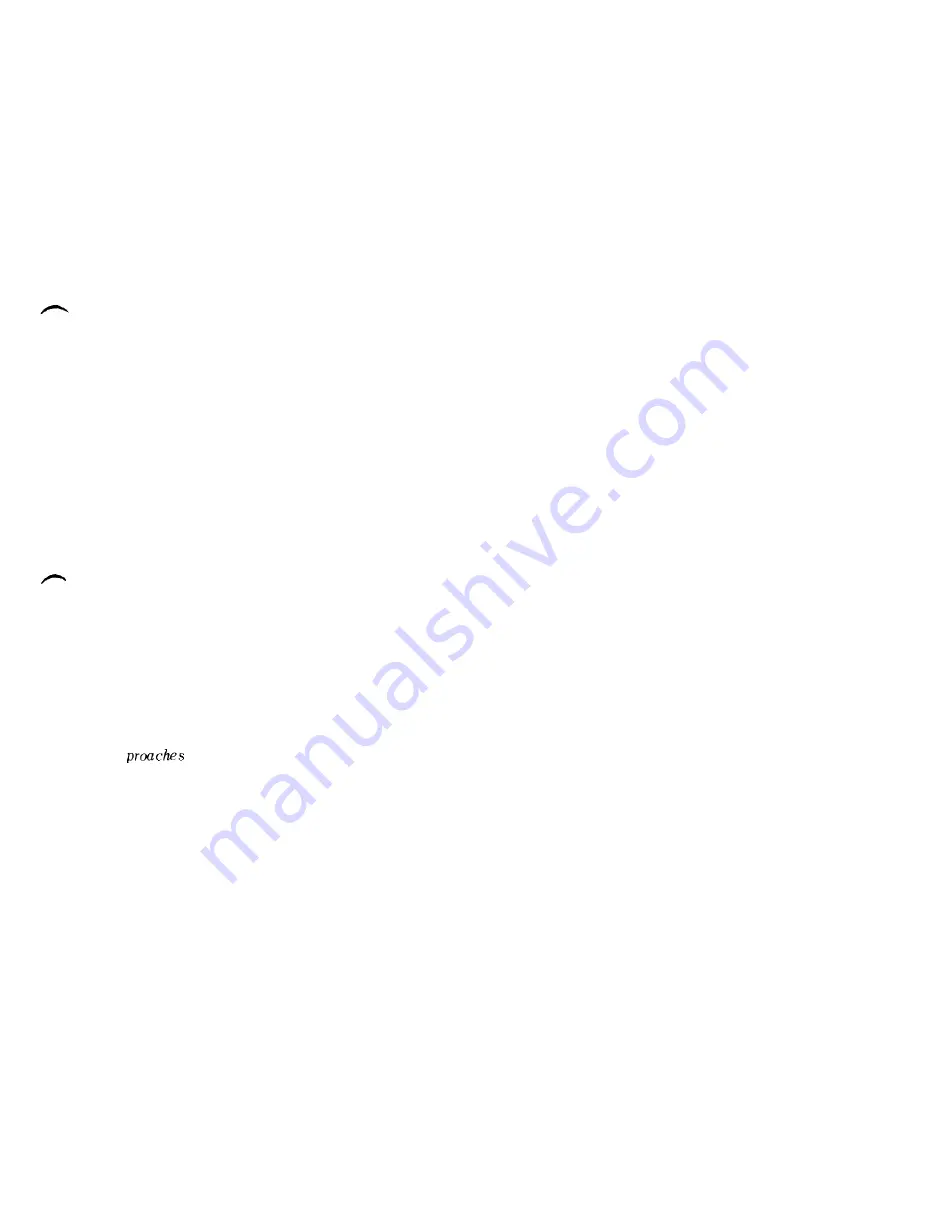

THERMOSTATIC EXPANSION VALVE

A.

B.

c.

D.

The expansion valve performs one specific func-

tion. It keeps the evaporator supplied with the

proper amount of refrigerant to satisfy the load

condition.

The sensing bulb of the expansion valve is in-

stalled in the closest straight run of suction line

from the cooler. The bulb is held on by clamps

around the suction line to assure firm contact with

the line. The suction line is then insulated to re-

duce the effect of surrounding ambients. In case

the bulb must be removed, simply slit the insulation

on each side of the bulb, remove the clamps and

then remove the capillary tubing that runs along

suction line from the valve.

The power element is removeable from the valve

body without removing the valve from the line.

This requires pumpdown.

Ambient temperature changes have an effect on the

performance of most thermostatic expansion valves.

With drop in ambient, the control bulb apparently

has a tendency

to

lose somcof its controlling char-

acteristics, which has the effect of increased super

heat. Consequently, special power elements for

thermostatic expansion valves unaffected by ambi-

ent are provided for all outdoor units.

CAUTION: Standard p ower

expansion valves should not

low ambient periods because,

summer conditions,

element thermostatic

be readjusted during

as ambient again ap-

the valve will flood

through and damage the compessor. Furthermore,

compressor manufacturers do not warrant compres-

sors obviously damaged by refrigerant flooding.

WATER COOLER

A. The water cooler is of the direct expansion type

with removable internally finned tubes and heavy

terneplate baffles. The copper tubes are individu-

ally rolled into heavy duty, steel tube sheets and

s c a l e d by a cast steel r e f r i g e r a n t h e a d .

B. The water connection nozzles which enter and

leave the shell are on the same side of the unit.

No special attention is required for the cooler

except that clean, filtered water should be supplied.

COOLER FREEZE PROTECTION

Cooler freeze protection is of major concern in the ap-

plication of air cooled water chillers. To protect

against freeze-up, a heater cable is provided as stan-

dard which protects the cooler to -2OF ambient out-

door air conditions. The control thermostat senses a

combination of ambient and cooler water temperature.

It thereby protects against water freezeup, at the same

time prevents excessively high water temperatures

during extended low ambient periods. Since there

would be no protection in the event of power failure,

or heater cable burnout, the following recommendations

are

A.

B.

C.

D.

intended to provide additional protection:

Drain the cooler and chilled water piping if the

chiller is not to be operatedover the winter months.

Two drain connections are provided on the cooler

to facilitate draining.

Maintain continuous water flow through the cooler

even when the compressors arc not operating.

Add ethylene glycol to the chilled water system to

provide antifreeze protection. Freeze point should

be approximately ten (10) degrees below minimum

design ambient temperature.

CAUTION: The use of ethylene glycol s o l u t i o n

will reduce the chiller capacity norma1ly b y 2 to 6

percen

t

depending on the concentration, and this

should be taken into consideration in system de-

sign.

Bypass water from the heating system through the

cooler during winter months. This can be accom-

plished by use of a small circulator pump arranged

to operate independently of the heating system and

p i p e d to maintain a small flow of water continu-

ously through the cooler. Water temperature must

not exceed 125F.

Page 27