20

McQuay IM 777-1

Service and Maintenance

Periodic Service and Maintenance

1

Check all moving parts for wear every six months.

2

Check bearing collar, sheave, and wheel hub setscrews,

sheave capscrews, and bearing hold-down bolts for

tightness every six months.

Ball Bearing Lubrication

1

Motor bearings—All ball bearings are prelubricated and do

not require additional grease at time of installation.

However, periodic cleaning out and renewal of grease is

necessary. Exercise extreme care to prevent foreign matter

from entering the bearing. It also is important to avoid over

greasing. Use a high grade, clean mineral grease with the

following characteristics:

•

Melting point over 302°F (150°C)

•

Free from oil and soap separation under operating and

storage conditions

•

Free of abrasive matter, acid, alkali and moisture

Specific greasing instructions are located on a label

attached to the fan section door.

2

Fan shaft bearings—All ball bearings are prelubricated and

do not require addition of grease at time of installation.

However, periodic renewal of grease is necessary.

Bearings are accessible through access door in fan section.

Grease fittings are located in front of door opening on

drive end of blower section. Apply grease slowly until a

very slight bleeding of grease from the seals is noted. Tie

hinged door(s) open.

Do not over lubricate.

Wipe off any

excess grease to prevent overheating.

The lubrication interval varies with the period of operation

and temperature of the ambient air. Use the guidelines in

the table below:

Note

: Temperature ranges over 225°F are shown for lubricants only. High

temperature applications are not suitable for standard air handler

components.

Fan Drive Adjustments

Upon completion of the air balance, replace the variable

pitched motor sheave with a properly sized, fixed sheave. A

matching fixed sheave provides longer belt and bearing life

and minimizes vibration. Initially, it is best to have a variable

pitched motor sheave for the purpose of air balancing. Once

the balance is achieved, fixed sheaves maintain balancing and

alignment more effectively. Replace the adjustable sheaves

with fixed sheaves.

With the electrical power disconnected, locked and tagged

out, measure the diameter of the V-belt outer surface where it

Table 12: Lubrication guidelines

Bearing operating temp range

Temperature

to 130°F

(54°C)

to 150°F

(66°C)

over 150°F

(66°C)

Continuous operation:

6 months

4 months

2 months

12-hr. day operation:

12 months

12 months

6 months

Table 13: Lubricants recommended for fan shaft ball

bearings

Manufacturer

Product name

Temp. range

°F

°C

Texaco Lubricants Company

Premium RB

–30 to 300 –34 to 149

Keystone Ind. Lubricants

81EP-2

0 to 250

–

18 to 121

Mobil Oil Corporation

Mobilith SCH100

–

40 to 350

–

40 to 177

Chevron U.S.A. Inc.

SRI-2

–

20 to 325

–

29 to 163

Exxon Company, U.S.A.

Ronex MP

–

40 to 300

–

40 to 149

Shell Oil Company

Alvania No. 2

–

20 to 240

–

29 to 116

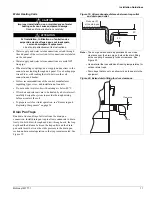

WARNING

Before servicing fans, lock out and tag out all power to the unit.

Fans or belts can cause severe personal injury or death.

AVERTISSEMENT

Avant de faire le service sur les ventilateurs,couper et indiquer

que le courant est coupé. Les ventilateurs ou les courroies

peuvent causer des blessures personnelles graves ou

entraîner la mort.

WARNING

Do not open the hinged access door and screw-fastened

access panels while the unit is operating. Moving parts and

strong suction forces can cause severe personal injury or

death

AVERTISSEMENT

Ne pas ouvrir les portes d’accès à charnières et les panneaux

à vis lorsque l’unité fonctionne. Les pièces mobiles et le niveau

de succion peuvent causer des blessures personnelles graves

ou même entraîner la mort.

Summary of Contents for Skyline IM 777-1

Page 32: ...30 McQuay IM 777 1...

Page 33: ...McQuay IM 777 1 31...

Page 34: ...32 McQuay IM 777 1...

Page 35: ......