24

McQuay IM 777-7

Operation Guidelines

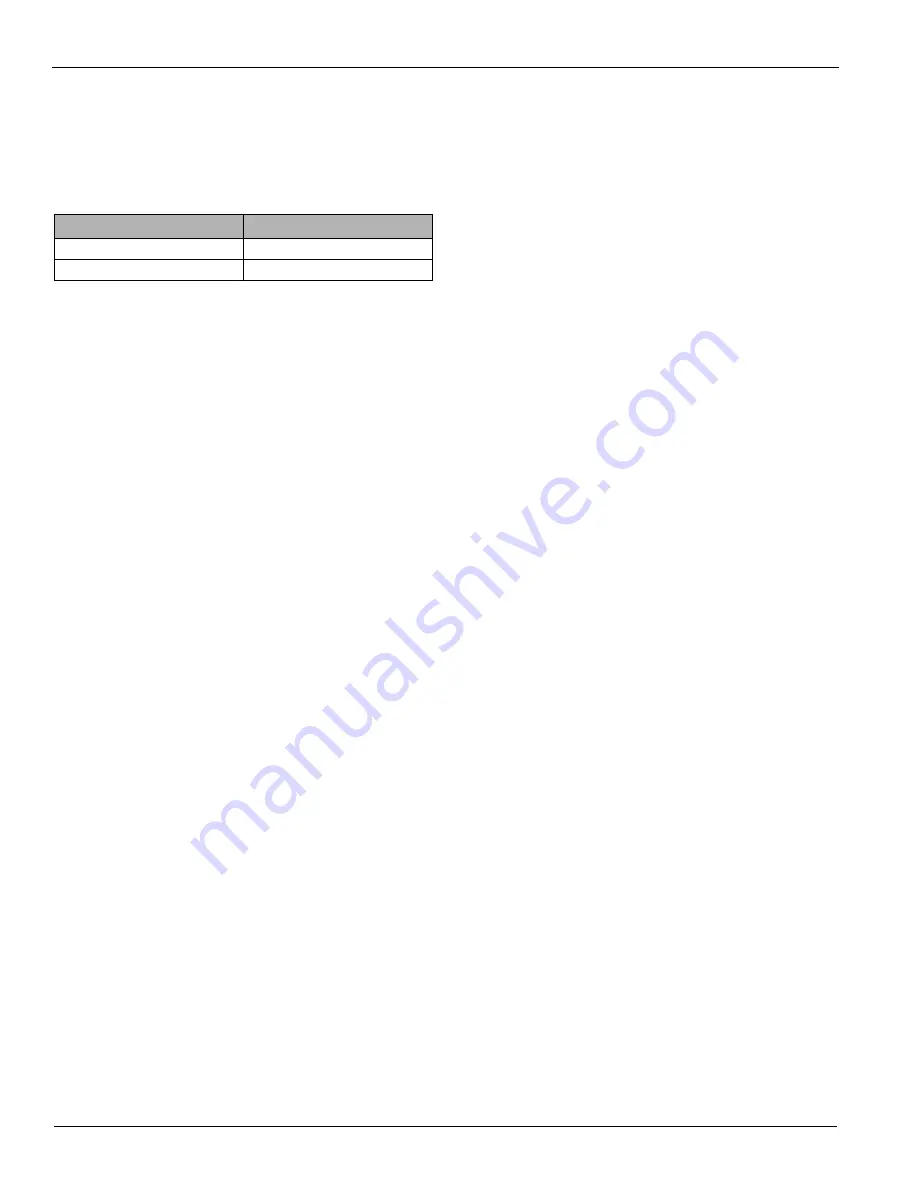

Fan Vibration Levels

Each unit as shipped is trim balanced to operate smoothly. To

provide satisfactory operation after shipping and installation,

use the accepted industry guidelines for field balancing fans.

See

Table 20

.

Note: Excessive vibration from any cause contributes to premature fan and

motor bearing failure. Monitor overall vibration levels every six

months of operation. An increase in levels is an indication of potential

trouble.

Vibration Causes

1

Wheel imbalance.

a

Dirt or debris on wheel blades.

b

Loose set screws in wheel hub or bearing-to-shaft.

c

Wheel distorted from overspeed.

2

Bent shaft.

3

Drive faulty.

a

Variable pitch sheaves—Axial and radial runout of

flanges; uneven groove spacing; out of balance. Also

similar faults in driven sheave.

b

Bad V-belts; lumpy, or mismatched; belt tension too

tight or too loose.

4

Bad bearings, loose bearing hold-down bolts

5

Motor imbalance

6

Fan section not supported evenly on foundation

Table 20: Vibration Levels

Fan speed (rpm)

Vibration

800 or less

5 mils maximum displacement

801 or greater

0.20 in/sec. maximum velocity