McQuay IM 777-7

27

Service and Maintenance

Figure 35: VP Type Sheave Adjustment

LVP Variable Speed Sheaves

Mounting

1

Slide sheave on motor shaft so that the side of the sheave

with setscrew

A

is next to the motor when setscrew

A

is

in the hub or barrel of the sheave.

2

When setscrew

A

is at an angle in the center flange

B

,

mount it away from the motor so that the outer locking

ring and flange can be removed to get to the setscrew.

3

To remove the flange and locking ring:

a

Loosen setscrews

D

.

b

Loosen but

do not remove

capscrews

E

.

c

Remove key

F

.

Note:

This key projects a small amount to provide a grip for

removing.

d

Rotate the flange counterclockwise until it disengages

the threads on the sheave barrel.

4

Verify that the driving and driven sheaves are in

alignment and the shafts are parallel. When aligning two-

groove sheaves, allow room between the sheave and

motor to access capscrews

E

.

5

Insert key

C

between the sheave and the shaft and tighten

setscrew

A

securely.

6

If flange and locking ring have been removed, when

replacing them make sure that the inner and outer flanges

are open from the closed position by the same amount as

the other flange. Determine this by accurately measuring

the top width of the grooves.

7

Insert key

F

.

8

Tighten setscrews

D

and capscrews

E

.

9

Put on belts and adjust belt tension.

Do not force belts

over grooves.

See

Fan Drive Belt Adjustment‚ page 30

.

10

Before starting the drive, ensure that all keys are in place

and all setscrews and all capscrews are tight. Check and

retighten all screws and retension belts after

approximately 24 hours of service.

Adjusting

1

Slack off belt tension if belts have been installed.

2

Loosen setscrews

D

.

3

Loosen but

do not remove

capscrews

E

.

4

Remove key

F

.

Note:

This key projects a small amount to provide a grip for

removing.

5

Adjust pitch diameter by opening or closing the movable

flanges by half or full turns.

Note:

Two-groove sheaves are supplied with both grooves

set at the same pitch diameter.

6

To provide the same pitch diameter for satisfactory

operation, move both movable flanges the same number

of turns. Do not open sheaves more than five turns for

A

belts or six turns for

B

belts.

7

Replace key

F

.

8

Tighten setscrews

D

and capscrews

E.

9

If belts have been installed, readjust belt tension. If belts

have not been installed, install them and adjust belt

tension.

Do not force belts over grooves.

See

Fan Drive

Belt Adjustment‚ page 30

.

10

Before starting the drive, ensure that all keys are in place

and all setscrews and all capscrews are tight. Check and

retighten all screws and retension belts after

approximately 24 hours of operation.

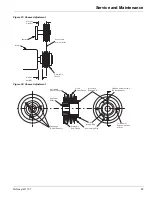

Figure 36: LVP Type Sheave Adjustment

Two Groove

C

A

B

B

D

E

C

A

B

E

D

C

Single Groove

Key

E

projects

to provide a grip

for removal.

Do not operate

sheeves with flange

projecting beyond

the hub end.

Section A-A

Section A-A

A

B

C

D

E

F

D

E

A

E

C

F

D

A

A