CSP

−

902RFM207E

−

1

ROTORCRAFT FLIGHT MANUAL

MD900 (902 Configuration with PW 207E)

Handling Servicing

and Maintenance

Revision 1

8

−

44

Reissue 2

DRY ENGINE MOTORING RUN

NOTE

:

This procedure is used to clear internally trapped fuel and vapor from the engine.

This procedure maybe used if there is evidence of a fire within the engine or lack

of EGT indication after lightoff at the beginning of an engine start.

Twist grip

OFF

Engine control switch for selected engine

SET TO IDLE

−

OBSERVE STARTER TIME LIMITS

Engine control switch for selected engine

OFF

EEC RESET button

PRESS

Twistgrip

PLACE IN NORMAL DETENT

EEC MAN or flashing indication

CHECK OFF

ENGINE WASH PROCEDURES

Engine Water Wash - Desalination

Open main transmission access door (Ref. Figure 8-6 and Figure 8-7).

NOTE

:

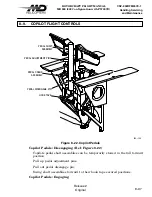

If cleaning agent is to be used, prepare solution and compressor wash system

in accordance with related manufacturers’ publications (Ref. RMM, Section

01

−

00

−

00)

Use of correct mixture as specified in the PWC Maintenance manual

is very important, not only when the temperature is below freezing

at the time of washing, but also if the temperature is expected to

be below 2

°

C (36

°

F) between time of washing and the next start.

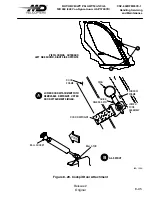

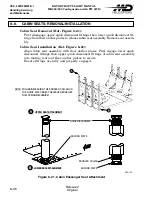

Connect cleaning solution or water source to engine wash panel using AN

type fittings.

NOTE

:

To prevent precipitation of deposits through the use of hard water, engine must

be allowed to cool to below 65

°

C (150

°

F). Minimum cooling period of 40 minutes

must be allowed since the engine was last operated.

Ensure inlet particle separator and heat / defog shutoff valves are

turned off.

Do not motor engine for more than 30 seconds.

NOTE

:

Ensure cleaning solution or water source pressure of

60

−

82 PSI

.

Perform dry engine motoring run; when N

G

reaches 5%, inject water solution

into air inlet case.

Close tank valve as soon as N

G

falls to 5%.

CAUTION

CAUTION

Summary of Contents for MD900 Explorer

Page 4: ......