Optional Equipment

Rotorcraft Cargo Hook Kit

CSP

−

902RFM207E

−

1

ROTORCRAFT FLIGHT MANUAL

MD900 (902 Configuration with PW 207E)

FAA Approved

Reissue 2

Original

10

−

16

PART III

EMERGENCY AND MALFUNCTION PROCEDURES

The presence of an external load may further complicate procedures following an

emergency or malfunction. Release of loads attached through the cargo hook should

be considered consistent with safety of flight factors.

Emergency Release:

Actuate the mechanical release handle, mounted on the cyclic stick, to release

cargo in the event of an electrical failure.

PART IV

NORMAL PROCEDURES

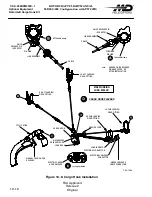

Preflight Checks (Ref. Figure 10-8):

Verify security of cargo hook bridle attach points.

Visually inspect hardware for damage or indications of possible fatigue.

Check for fraying, wear or any other form of damage to the cable bridle assembly.

Inspect electrical release, and load indicating wire harness and connectors for gener

al condition and security.

Examine manual release cable housing for nicks, cuts, kinks or general damage

that might restrict movement of cable within housing.

Inspect manual release connector for general condition and security.

Ensure a service loop is present in the manual release cable at cargo hook.

Inspect hook for general condition.

Cargo Hook Operational Checks:

NOTE

:

Functional checks of the cargo hook require an external power source for

electrical power or an operating engine.

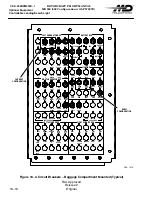

Ensure that the

CRGO HOOK

circuit breaker (left generator bus) is IN.

NOTE

:

Refer to Chapter 25

−

55

−

00 in the RMM for special functional checks required

following the initial installation of the cargo hook kit or following replacement of

the manual release cable.

Summary of Contents for MD900 Explorer

Page 4: ......