Document No

7215-D0006-02

10

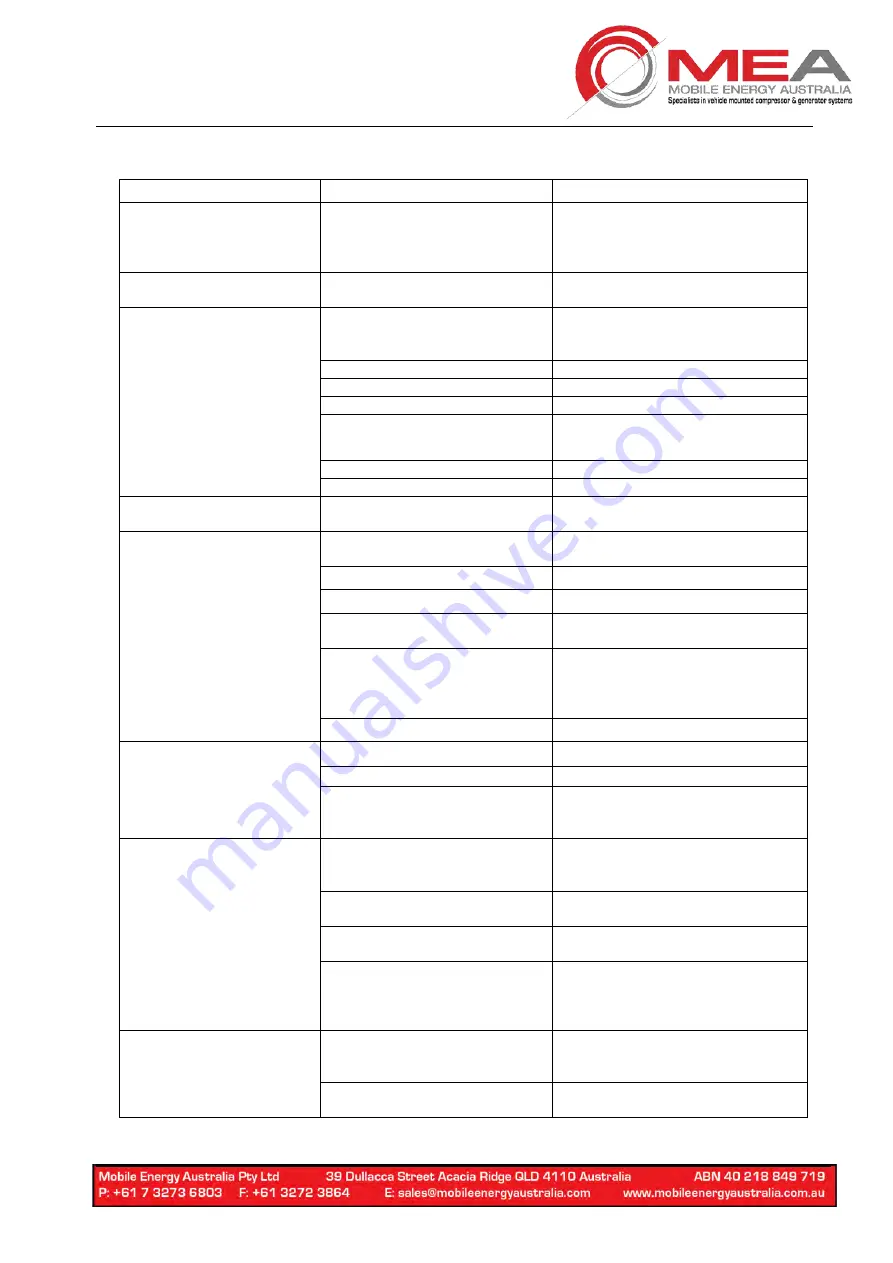

7. TROUBLESHOOTING

(Detailed procedures on troubleshooting of the compressor system can be found in

“Compressor

Information (APPENDIX-A)”.

Fault

Possible cause

Remedy

Not functioning

Control box or electrical

connection faulty

Have control box or electrical

connection repaired. Incorrect

rotation direction Phases reversed

Reconnect

Incorrect rotation direction

Hoses are connected wrongly

Reconnect supply and return hoses

Screw compressor system

has difficulty starting

Flow and pressure not

insufficient

Inspect

Drive transmission ratio too fast

Check flow and pressure

Star-delta switchover incorrect

Set

Compressor is flooded with oil

Check

System has not been

depressurized yet

Check, depressurize if necessary

Ambient temperature too low

Check viscosity of the oil

Oil filling too viscous

Check viscosity of the oil

Pressure losses at

filter cartridges

Excessive pressure loss at

air-oil separating element

Replace air-oil separating element

Combistat switches off

due to excessively high

temperature

Oil shortage

Check the oil level in the oil

reservoir, fill if necessary

Oil filter soiled

Replace oil filter cartridge

Oil thermostat faulty

Replace oil thermostat

Oil cooler soiled

Clean oil cooler on air side, clean

on oil side if necessary

Incorrect setup

a) Room ventilation

b) Exhaust air obstructed

c) Thermal short-circuit

Follow recommendations for

installation of the compressor

system

Combistat defective

Replace combistat

Safety valve blows off

(at a permissible operating

pressure)

Safety valve defective

Replace safety valve

Air-oil separating element dirty

Replace air-oil separating element

Compressor system does not

switch off automatically, control

valve operates intermittently

Check the solenoid valve, replace

if necessary

Oil in compressed air

Operating pressure and

delivery quantity is not in the

permissible range

Check pressures

Oil exhaust system

contaminated

Clean oil extraction system

Air-oil separating element faulty

Check air-oil separating element

and replace if necessary

Oil level in oil reservoir

too high; possibly

excessive condensate

Observe oil level marking; drain

and replace if necessary

Compressor system is not

discharged during

continuous operation,

system does not switch off

automatically in case of

Upper switching point of

network pressure monitor set

too high

Readjust network pressure monitor

Solenoid valve defective

Relief valve defective

Replace solenoid valve/ relief valve

Summary of Contents for SMAC 90-H

Page 2: ...Document No 7215 D0006 03 THIS PAGE IS LEFT BLANK INTENTIONALLY...

Page 12: ...Document No 7215 D0006 02 8...

Page 17: ...Document No 7215 D0006 02 13 9 DRAWINGS ILLUSTRATIONS SMAC 90 H GENERAL ARRANGEMENT DRAWINGS...

Page 18: ...Document No 7215 D0006 02 14...

Page 19: ...Document No 7215 D0006 02 15...

Page 20: ...Document No 7215 D0006 02 16...

Page 21: ...Document No 7215 D0006 02 17...

Page 22: ...Document No 7215 D0006 02 18...

Page 23: ...Document No 7215 D0006 02 19...

Page 24: ...Document No 7215 D0006 02 20...

Page 25: ...Document No 7215 D0006 02 21 SMAC 90 H HYDRAULIC CIRCUIT...

Page 26: ...Document No 7215 D0006 02 22 HARNESS SMAC 40H 90H FRAMED 12V AND 24V...

Page 27: ...Document No 7215 D0006 02 23...

Page 28: ...Document No 7215 D0006 02 24 SMAC H COMPRESSOR REMOTE ELECTRONIC CONTROL WIRING 12 or 24V...

Page 29: ...Document No 7215 D0006 02 25...

Page 33: ...Document No 7215 D0006 02 29 APPENDIX A COMPRESSOR INFORMATION...

Page 34: ...Document No 7215 D0006 02 30...

Page 35: ...Document No 7215 D0006 02 31...

Page 36: ...Document No 7215 D0006 02 32...

Page 37: ...Document No 7215 D0006 02 33...

Page 38: ...Document No 7215 D0006 02 34...

Page 39: ...Document No 7215 D0006 02 35...

Page 40: ...Document No 7215 D0006 02 36...

Page 41: ...Document No 7215 D0006 02 37...

Page 42: ...Document No 7215 D0006 02 38...

Page 43: ...Document No 7215 D0006 02 39...

Page 44: ...Document No 7215 D0006 02 40...

Page 45: ...Document No 7215 D0006 02 41...

Page 46: ...Document No 7215 D0006 02 42...

Page 47: ...Document No 7215 D0006 02 43...

Page 48: ...Document No 7215 D0006 02 44...

Page 49: ...Document No 7215 D0006 02 45...

Page 50: ...Document No 7215 D0006 02 46...

Page 51: ...Document No 7215 D0006 02 47...

Page 52: ...Document No 7215 D0006 02 48...

Page 53: ...Document No 7215 D0006 02 49...

Page 54: ...Document No 7215 D0006 02 50...

Page 55: ...Document No 7215 D0006 02 51...

Page 56: ...Document No 7215 D0006 02 52...

Page 57: ...Document No 7215 D0006 02 53...

Page 58: ...Document No 7215 D0006 02 54...

Page 59: ...Document No 7215 D0006 02 55...

Page 60: ...Document No 7215 D0006 02 56...

Page 61: ...Document No 7215 D0006 02 57...

Page 62: ...Document No 7215 D0006 02 58...

Page 63: ...Document No 7215 D0006 02 59...

Page 64: ...Document No 7215 D0006 02 60...

Page 65: ...Document No 7215 D0006 02 61...

Page 66: ...Document No 7215 D0006 02 62...

Page 67: ...Document No 7215 D0006 02 63...

Page 68: ...Document No 7215 D0006 02 64...

Page 69: ...Document No 7215 D0006 02 65...

Page 70: ...Document No 7215 D0006 02 66...

Page 71: ...Document No 7215 D0006 02 67...

Page 72: ...Document No 7215 D0006 02 68...

Page 73: ...Document No 7215 D0006 02 69...

Page 74: ...Document No 7215 D0006 02 70...

Page 75: ...Document No 7215 D0006 02 71...

Page 76: ...Document No 7215 D0006 02 72...

Page 77: ...Document No 7215 D0006 02 73...

Page 78: ...Document No 7215 D0006 02 74...

Page 79: ...Document No 7215 D0006 02 75...

Page 80: ...Document No 7215 D0006 02 76...

Page 81: ...Document No 7215 D0006 02 77...

Page 82: ...Document No 7215 D0006 02 78...

Page 83: ...Document No 7215 D0006 02 79...

Page 84: ...Document No 7215 D0006 02 80...

Page 85: ...Document No 7215 D0006 02 81...

Page 86: ...Document No 7215 D0006 02 82...

Page 87: ...Document No 7215 D0006 02 83...

Page 88: ...Document No 7215 D0006 02 84...

Page 89: ...Document No 7215 D0006 02 85...

Page 90: ...Document No 7215 D0006 02 86...