www.procontechnology.com.au

11 Phone: (03) 98306288

5. EMI

DC-DC converters are manufactured to comply with electro-magnetic interference (EMI) standards (refer to relevant

specification). Depending on the wiring of the unit, load and grounding, the unit may not function correctly. To ensure optimal

use of the DC-DC converter, consider the following steps:

a. Separate Input and Output Wires

If the input and output wires are too close to each other, induced noise on the output terminal increases. Typically, if the noise

terminal voltage of the input line increases, noise radiation (noise field intensity) from the equipment increases. Also, if the

input line and the internal circuits (digital circuits, in particular) of the equipment are too close to each other, the noise terminal

voltage increases and the equipment may not operate properly. Make sure that the input cables are separated from any low

voltage internal circuits of the equipment.

b. Short, Thick Wires

Input and output wires on the equipment should be short and thick. Each set of two wires should either be attached or bundled

in parallel or twisted together. If wires are looped, the noise and interference from the DC-DC converter will be affected.

6. RELIABILITY

6.1 LIFE CYCLE AND BREAKDOWN

DC-DC converters have proven to be highly reliable when used in household appliances and industrial products and are highly

rated throughout industry.

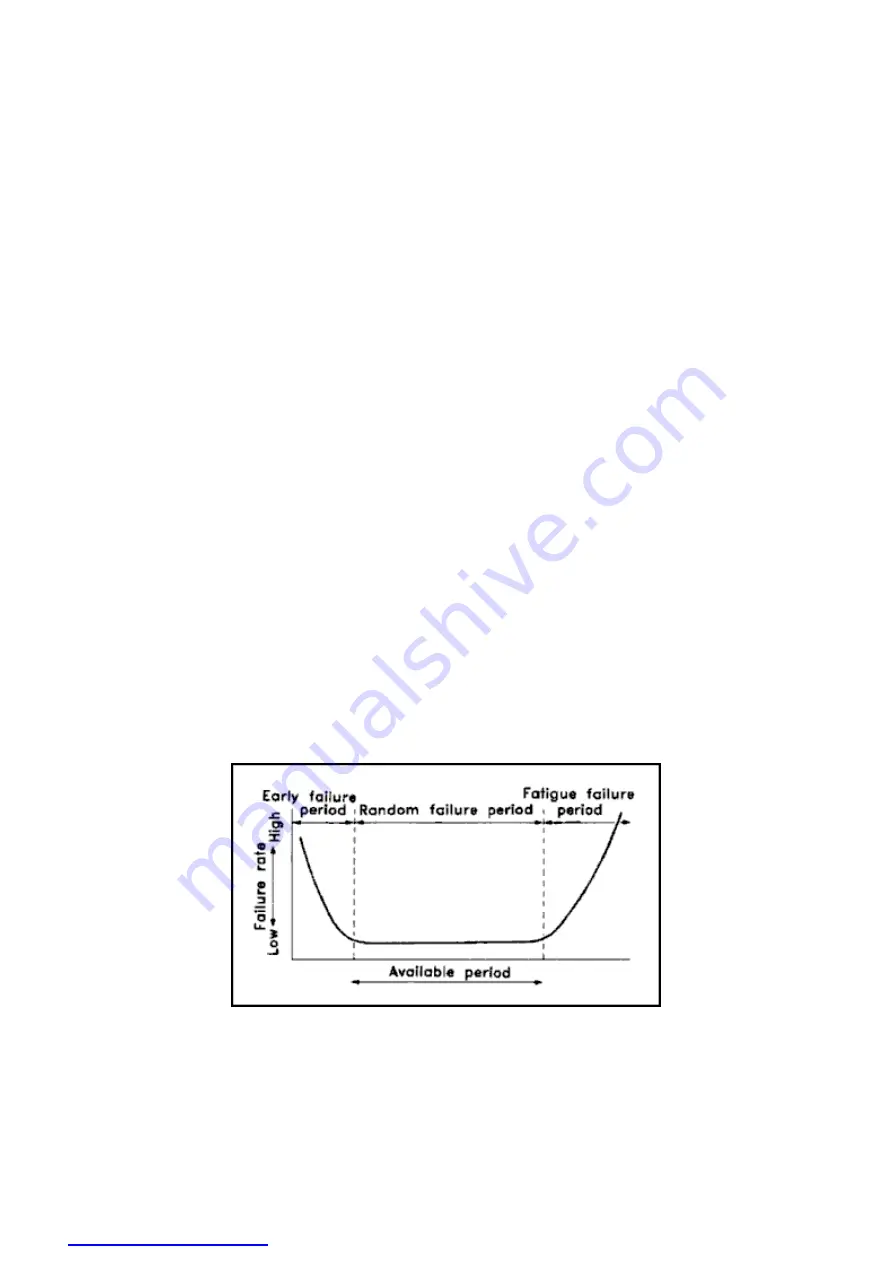

The following figure shows the failure rate curve (bathtub curve) during a typical product life cycle.

The Early Failure Period - to prevent early failure, each manufacturer screens out parts or performs aging tests on the finished

product. When Mean Well DC-DC converters are delivered to customers, the power supplies have already entered the random

failure period.

Random Failure Period - the stability of each DC-DC converters depends on its own reliability (Mean Time Between Failure:

MTBF).

Basically, the failure rate is very low. However, the failure rate in the random failure period differs depending on installation

and operating conditions (ambient temperature, installation method, derating, ventilation, vibration and shock) which are

determined by the user.

Fatigue Failure Period - At some time, the DC-DC converters will enter the fatigue failure period.

Fig. 20

6.2 AMBIENT TEMPERATURE AND SERVICE LIFE

High efficiency switching at a high frequency, improvement in parts and integrated technology has greatly reduced the size of

DC-DC converters. Integration density has allowed the internal parts to be packed closer together.

Each part of a DC-DC converters distinctly differs in its service life depending on the ambient temperature.