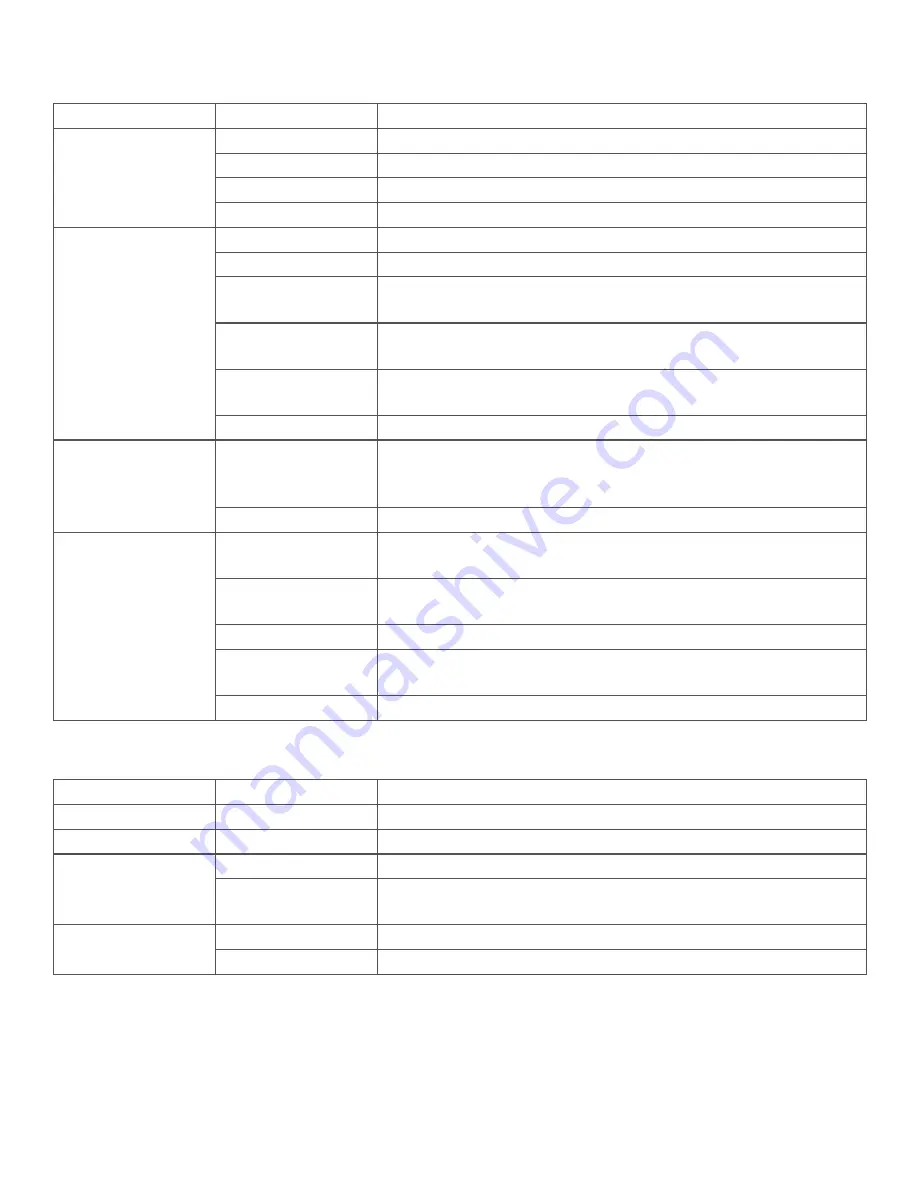

LED indicators

Table 10. LED specifica ons – normal opera ng mode

Label

State

Descrip on

1: POWER

Steady yellow

Device is boo ng up.

Steady green

Device boot is successful.

Blinking yellow

Device is shu ng down.

Off

Device is off.

2: STATUS

Blinking yellow

Device is configuring hardware.

Steady green

Hardware configura on is complete.

Flashing green

100 ms on, 2s off

Wai ng for the schedule start condi on to be met. (

)

Blinking heartbeat

The configured schedule start condi on is met; wai ng for job

start condi on to be met. (

Blinking green

The configured job start condi on is met – the job is running.

)

Off

Device is off.

3: ERROR

Blinking yellow

Error condi on is detected. LED blinks even when the so ware

is configured to ignore the error.

Error state is cleared on the next schedule start.

Off

No error is detected, or the device is off

4: MEDIA

Blinking yellow

A job is configured to log to external media, but the job hasn't

started yet; push bu on will not let you eject media.

Steady yellow

External media is inserted into the SD card slot or USB storage

port.

Blinking green

Currently logging to an external SD card or USB storage device.

Steady green

Media has been made safe for removal using the FUNC bu on,

but is s ll inserted in the device.

Off

No external media is detected, or the device is off.

Note 5. Use the WebDAQ so ware to configure start and stop se ngs for jobs and schedules.

Table 11. LED specifica ons – so ware update mode

LED

State

Descrip on

All LEDs

Solid yellow

So ware update is star ng.

1. POWER

Blinking yellow

So ware update is running.

2. STATUS

Blinking green

Update file is located; device is being updated.

Blinking yellow

Update file cannot be located; insert media containing the

update file.

3. ERROR

Blinking green

Update is successful; device reboot in approximately 5 seconds.

Blinking yellow

Update failed; user must retry.

WebDAQ 316 User's Guide

page 26