Power-On Mode

WebDAQ Series hardware can be configured to start automa cally when power is applied, instead of requiring

users to press the POWER bu on. This is useful if the WebDAQ is opera ng in a remote loca on and a power

loss occurs. This "power-on mode" is enabled by removing a 2-pin jumper (labeled W1) from the WebDAQ

circuit board.

When jumper W1 is removed, the device does not shutdown completely unless the power adapter is

unplugged from the device or power source.

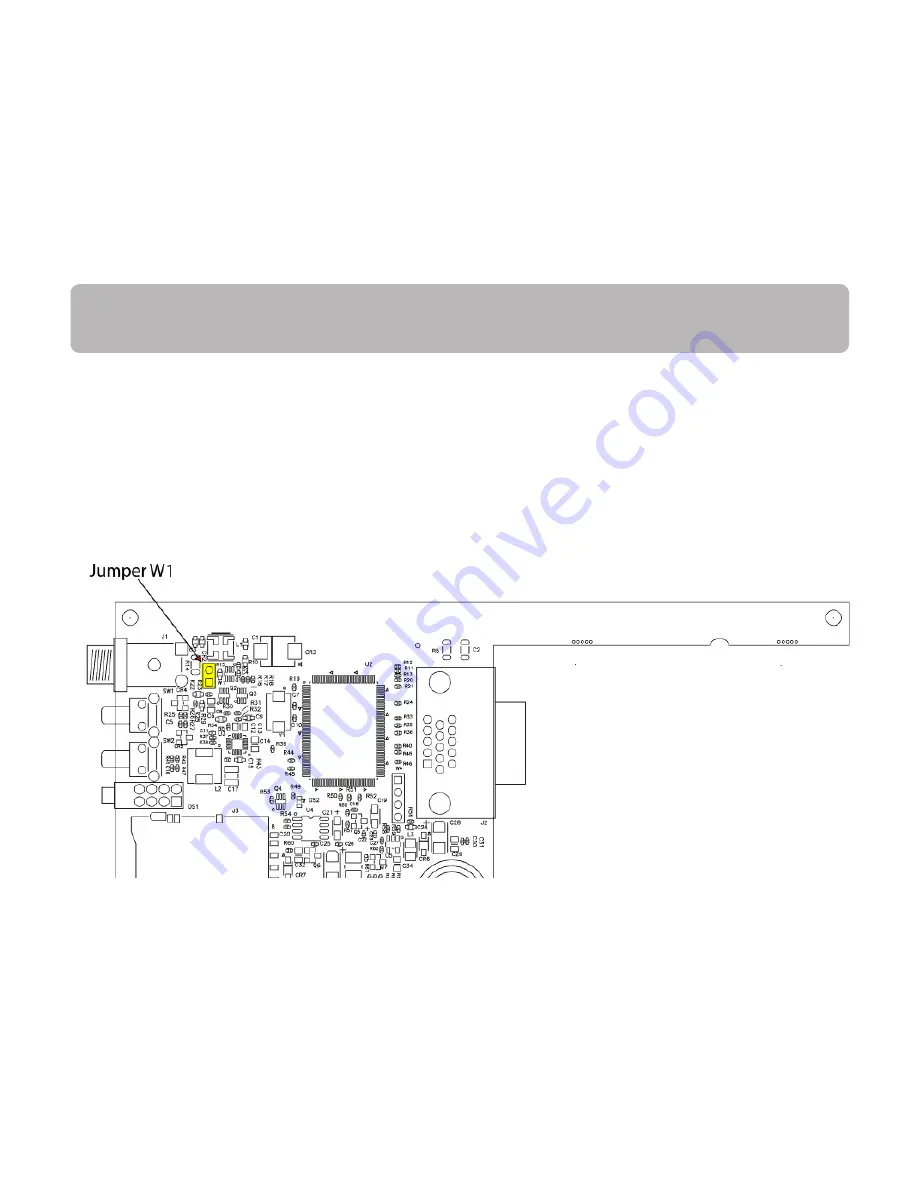

Perform the procedure below to remove jumper W1 from the WebDAQ circuit board and enable power-on

mode.

Cau on! The discharge of sta c electricity can damage some electronic components. Before removing

the WebDAQ device from its housing, ground yourself using a wrist strap or touch the computer chassis

or other grounded object to eliminate any stored sta c charge.

1. Power down the WebDAQ device and disconnect the power supply.

2. On the rear panel, remove the Ethernet cable, power cable, SD card, and any USB devices.

3. Remove the #6-32 ground screw.

4. Remove the nut and washer from the EXT PWR connector.

5. Remove the two front panel bezel screws and remove the front bezel.

6. Slide out the circuit board with the front panel intact.

7. Remove jumper W1 from the specified loca on shown below.

8. Slide the circuit board back into the enclosure.

9. A ach the front bezel and secure with the two bezel screws removed in step 5.

10. Secure the power connector with the nut and washer (removed in step 4) to the power connector, and

a ach the ground screw, Ethernet and power cables, and any USB devices.

To automa cally run a schedule when the WebDAQ powers up, enable the "Automa cally start schedule on

system startup" op on on the Schedule Se ngs dialog box of the web interface. If a power cycle occurs, the

schedule will restart from the beginning, regardless of which job was running when the power was lost. In

order to retain the data from each schedule start, make sure to set the logging op on for each job to "Append

Date/Time to File Name" so that each run a er power loss creates a new data file rather than overwri ng the

original file. Refer to the WebDAQ help for details about how to configure schedule and logging op ons.

WebDAQ 504 User's Guide

page 17