Page 23

1330SE - Servce & Parts Manual

November 2021

Secton 10 - Mantenance

Annual Inspection Checklist

THIS CHECKLIST MUST BE USED AT 12-MONTH INTERVALS OR EVERY

600 HOURS OF MACHINE USE, WHICHEVER OCCURS FIRST. FAILURE

TO DO SO COULD RESULT IN DEATH OR SERIOUS INJURY.

Annual Maintenance Inspections should be conducted by qualified service technicians only.

Photocopy the Annual Inspection Checklist page from the Operator’s Manual to keep record of

this inspection. Keep inspections records up to date. Record and report all discrepancies to your

supervisor.

Perform all checks listed on Pre-Start Inspection and the Frequent Inspection, then check all items

listed on the Annual Inspection Report. See specific instructions below.

Scissor Slide Blocks

Maintaining the condition of the scissor arm slide blocks is essential to safe machine operation.

Continued use of worn out wear pads may result in component damage and unsafe operating

conditions.

Perform this procedure with the platform in the stowed position.

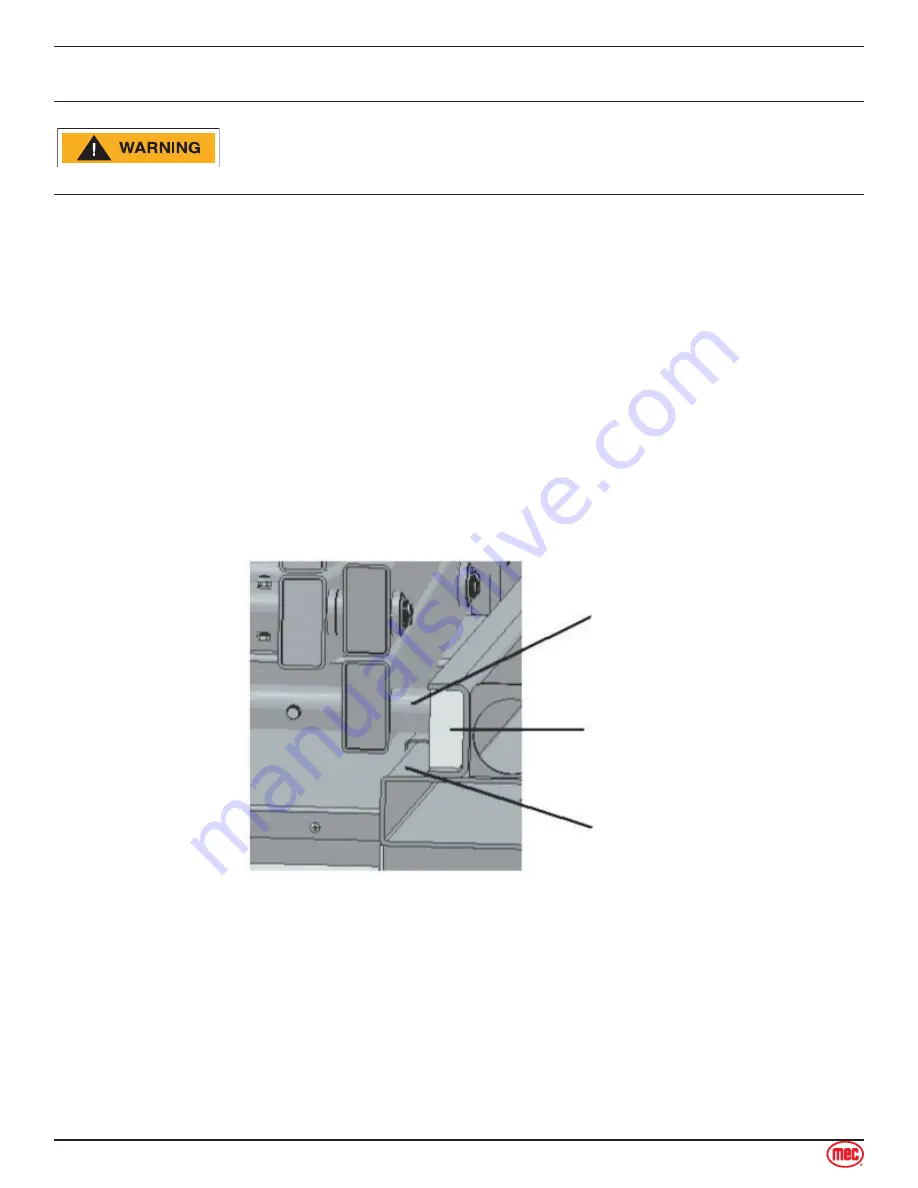

ART_5051

Slide Block

Inner Arm

Cross Tube

Chassis Deck

Measure the distance between the number one inner arm cross tube and the chassis deck at the

ground controls side of the non-steer end of the machine.

Result:

The measurement is 1.18 in / 30 mm or more. Proceed to step 2.

Result:

The measurement is less than 1.18 in / 30 mm. Replace both wear pads.

Measure the distance between the number one inner arm cross tube and the chassis deck at the

battery pack side of the non-steer end of the machine.

Result:

The measurement is 1.18 in / 30 mm or more. Proceed to step 3.

Result:

The measurement is less than 30 mm. Replace both wear pads.

Apply a thin layer of dry film lubricant to the area of the chassis where the scissor arm wear pads

make contact.

1.

•

•

2.

•

•

3.