Page 2-8

May 2005

1532ES / 1932ES Operator’s Manual

PRESTART INSPECTION

Before use each day or at the beginning of each shift, the machine shall be given a visual

inspection and functional test. Repairs (if any) must be made prior to operating the machine

as it is critical to ensure safe operation of the machine.

♦

Visually inspect all machine components; for loose or missing parts, hydraulic

fluid leaks, loose or damaged wires. Check for structural or weld cracks.

♦

Check fluid levels with the platform fully lowered.

♦

Check the wheel lug nuts for tightness (Refer to “Machine Specifications”).

♦

Check that all warning and instructional labels are legible and secure.

♦

Check the platform guard rail system. Insure platform entry properly closes and

secures.

♦

Ensure that emergency stop buttons on the base control panel and the platform

controls are disengaged. Reset by turning clockwise.

♦

Ensure that the battery disconnect switch is in the “ON” position.

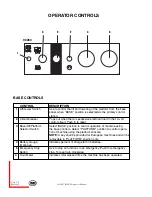

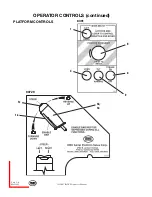

MACHINE START UP

1. Ensure the battery disconnect switch, located on Base Control Box, is in the “ON”

position.

2. Place the base/platform select switch to the desired position.

3. The machine can now be operated from the selected position.

NOTE:

If the machine fails to operate, inspect the motor controller inside the motor

compartment. A green LED located on the controller should be illuminated.

If the LED is not illuminated, refer to the troubleshooting section.

Summary of Contents for 1532ES

Page 2: ......

Page 7: ...Page 1 1 1532ES 1932ES Operator s Manual May 2005 SECTION 1 SAFETY ...

Page 17: ...Page 2 1 1532ES 1932ES Operator s Manual May 2005 SECTION 2 OPERATION ...

Page 34: ...Page 2 18 May 2005 1532ES 1932ES Operator s Manual ...

Page 35: ...Page 3 1 2033ES 2633ES Operator s Manual May 2005 SECTION 3 MAINTENANCE ...

Page 46: ...Page 3 12 May 2005 1532ES 1932ES Operator s Manual ...