Page 41

Speed Level Seres - Servce & Parts Manual

January 2019

Secton 5 - Hydraulc System

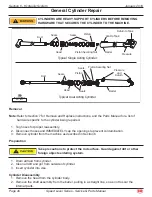

Insert shaft into a

soft jawed

vise so that the head and piston can be removed. Be sure the

shaft and vise are both clean before using.

Remove nut at the end of the shaft and pull head and piston off of the rod.

Remove all seals from the head and piston using a non-sharp seal tool. These tools are

available from various seal suppliers.

Clean all fluid and debris off of the head, piston, shaft, collar and barrel using solvent, rags, and

an air hose.

Inspect parts for scratches, pits or polishing. Check seal groves and sealing surfaces.

Scratches or pits deep enough to catch the fingernail are unacceptable; replace the cylinder.

Polishing is a sign of uneven loading. Check for roundness. If a polished surface is not round

within .007 in. (0.18 mm) replace the cylinder.

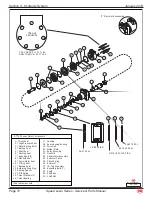

Cylinder Assembly

To insure a quality repair, cylinder parts must be thoroughly cleaned, dry, and

free of solvents, and assembly must be performed in a clean area free of dust

and contamination.

Do not use sharp edged tools during seal replacement. After installing seals

wait at least one hour before assembling the cylinder to allow the seals to

return to their original shape.

Torque all hardware according to the Hydraulic Components Torque Table

unless otherwise specified.

Lubricate all components with clean hydraulic fluid.

Install new seal kit components. Install all seals on the head and piston using the non-sharp seal

tool.

Place a small amount of fluid on the inside head seals. Reinstall the head on the shaft by

slipping head over the piston end of the shaft. Be very careful not to damage the inside seals.

Place a small amount of fluid on the inside seals of the piston. Reinstall the piston on the shaft

by slowly twisting the piston onto the threads of the shaft. Be very careful not to damage the

inside seals.

Reinstall the shaft nut. Torque 1 ½” nut to 160 ft. lbs. (216 Nm).

Grease the outside seals of the head and piston.

Reinstall the shaft into the barrel of the cylinder and push in until groove of the head lines up

with the slot in the barrel.

Reinstall the cylinder retainer. Installation is reverse of removal.

Cycle the cylinder using air to check for proper operation.

Note:

Keep all parts clean when working with hydraulic cylinders. Even one small piece of dirt or grit

can damage the cylinder.

3.

4.

5.

6.

7.

•

•

1.

2.

3.

4.

5.

6.

7.

8.

9.