Page 45

Speed Level Seres - Servce & Parts Manual

January 2019

Secton 6 - Electrcal System

Batteries

Discharged batteries can freeze, causing damage to the battery and/or

battery case������ A broken battery case will allow electrolyte to leak out������

CHARGING BATTERIES CREATE EXPLOSIVE HYDROGEN GAS������ KEEP

SPARKS, FLAMES AND SMOKING MATERIALS AWAY FROM BATTERIES������

ALWAYS WEAR SAFETY GLASSES WHEN WORKING WITH BATTERIES������

BATTERY FLUID IS CORROSIVE������ THOROUGHLY RINSE SPILLED FLUID

WITH CLEAN WATER������

REPLACE ONLY WITH MANUFACTURER-APPROVED BATTERIES������

BEFORE DISCONNECTING THE BATTERY NEGATIVE (–) LEAD, MAKE

SURE THAT ALL SWITCHES ARE OFF������ IF ON, A SPARK WILL OCCUR AT

THE GROUND TERMINAL THAT COULD IGNITE HYDROGEN GAS OR

FUEL VAPORS������

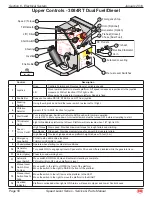

3084RT

One (1) battery (12 Volts DC) supplies the electrical power required to start the engine and

operate the electrical circuits.

3084ES

Eight (8) batteries (6 Volts DC) supply power required to operate the machine.

Battery Maintenance (In Storage)

Follow these procedures for maintenance of battery on a machine not in use:

Keep battery clean. Electrolyte of batteries should be checked regularly and kept at proper level.

Never stack one battery directly on top of another because post or container damage can result.

If batteries are stored individually, place supporting boards between layers. Rotate stock so that

the oldest batteries are used first.

Batteries should be kept fully charged. A battery, while in storage, should be recharged to full

charge at recommended intervals.

A battery fully (100%) charged at 80°F (26������6°C)

Drops to 65% at 32°F (0°C)

Drops to 40% at 0°F (-32°C)

Recommended Battery Charge Intervals

If Stored At

Recharge

Below 40°F (4°C)

Every week

40°-60°F (4°-15°C)

Every 2 weeks

Above 60°F (15°C)

Every month

Battery Maintenance (In Use)

Check battery and surrounding area for signs of damage or corrosion.

•

•

•

•

•

•