Page 23

3084ES Speed Level

TM

- Operator’s Manual

August 2020

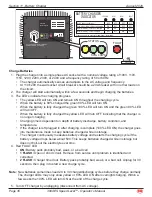

Machine Inspections

DO NOT operate this machine until you have read and understood the Safety section of this

manual, have performed the Pre-Start Inspection, Routine Maintenance, and Functions Test,

have inspected the jobsite for hazards, and have learned the operating procedures for this

machine�����

The operator must conduct a thorough Pre-Start Inspection of the machine and test all functions

before each work shift to check for damage, malfunction and unauthorized modification.

Tag and remove a damaged, malfunctioning or modified machine from service. DO NOT use a

damaged, malfunctioning or modified machine.

Use the Pre-Start Inspection to determine what Routine Maintenance is required. The operator may

perform only the routine maintenance items specified in this manual.

IMPORTANT:

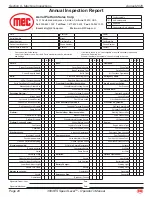

Scheduled maintenance inspection checklists are included in this manual for use

only by qualified service technicians. Only qualified service technicians may perform

repairs to the machine. After repairs are completed, the operator must perform a Pre-

Start Inspection before proceeding to the Functions Test.

Never perform service on the machine with the platform elevated without

first blocking the elevating assembly (see Support the Platform on page

32)�����

Never leave hydraulic components or hoses open����� They must be

protected from contamination (including rain) at all times�����

Never open a hydraulic system when there are contaminants in the air�����

Always clean the surrounding area before opening hydraulic systems�����

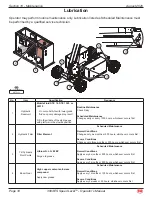

Use only recommended lubricants����� Improper lubricants or incompatible

lubricants may be as harmful as no lubrication�����

Watch for makeshift “fixes” which can jeopardize safety as well as lead

to more costly repair�����

Hydraulic fluid under pressure can penetrate and burn skin, damage

eyes, and may cause serious injury, blindness, and even death����� Correct

leaks immediately�����

Failure to perform preventive maintenance at recommended intervals

may result in the unit being operated with a defect that could result in

injury or death of the operator�����

Immediately report to your supervisor any Defect or malfunction�����

Any defect shall be repaired prior to continued use of the aerial work

platform�����

Secton 9 - Machne Inspectons

Machine Inspections