Page 25

3084ES Speed Level

TM

- Operator’s Manual

August 2020

Secton 9 - Machne Inspectons

Pre-Start Inspection Checklist

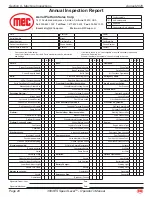

The operator must conduct a thorough Pre-Start Inspection of the machine before each work shift

– see “Machine Inspections” on page 23.

General Inspection Checklist

Check that the operator’s, safety, and responsibilities manuals are in the storage container located on the

platform.

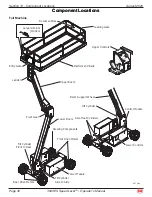

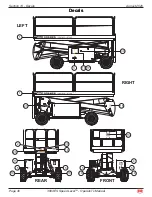

Perform a visual inspection of all machine components. Look for missing parts, torn or loose hoses,

hydraulic fluid leaks, torn or disconnected wires, damaged tires etc.

Check all structural components of the machine for cracked welds, corrosion and collision damage.

Check all hoses and the cables for worn or chafed areas.

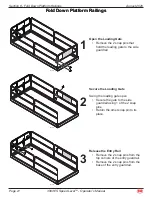

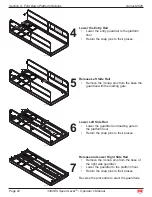

Check the platform rails and sliding mid-rail entry for damage or modification

Check that all warning and instructional labels are legible and secure.

Check the tires for damage.

Check the tire pressure (not required for foam filled tires).

Check the lower limit switch for visual damage or loose or missing hardware.

All structural components, pins and fasteners are present and properly tightened.

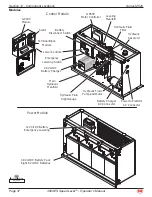

Fluid Level Checklist

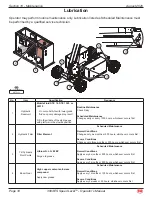

Check for fluid leaks.

Hydraulic fluid level (check with platform fully lowered).

Secure for operation

Secure all covers and panels. Perform Routine Maintenance as needed, then proceed to the Functions

Test.

DATE

INSPECTED BY