Page 84

45-J Desel - Servce & Parts Manual

January 2022

Secton 18 - Mechancal Components

Swing Bearing/Turntable Components

THIS PROCESS REQUIRES SPECIFIC REPAIR SKILLS AND

EXPERIENCE, APPROPRIATE LIFTING EQUIPMENT AND A PROPER

WORKPLACE������ DEATH, SERIOUS INJURY OR SIGNIFICANT MACHINE

DAMAGE COULD OCCUR IF YOU ATTEMPT THIS PROCESS WITHOUT

THE APPROPRIATE SKILLS AND EQUIPMENT������

The Swing Bearing is located between the turntable and the machine chassis. It’s purpose is to

provide continuous turntable rotation.

Note:

The module doors and module contents are omitted from some of the following illustrations to

better show the disassembly process. It is not necessary to remove the doors or contents to

perform this procedure unless stated.

Disassembly

Park the machine on a firm level surface.

Thoroughly clean all hydraulic connections

and tag all hoses for proper reassembly before

disconnecting them. Immediately plug and cap all

openings to prevent contamination. Tag electrical

connections before disconnecting them.

Remove the Platform/Jib assembly as described in

steps 1 through 12 of the Platform Level Cylinder

removal procedure on page 74.

Disassemble the boom linkage as described in the

Boom Lift Cylinder/Boom Linkage procedure on

page 78.

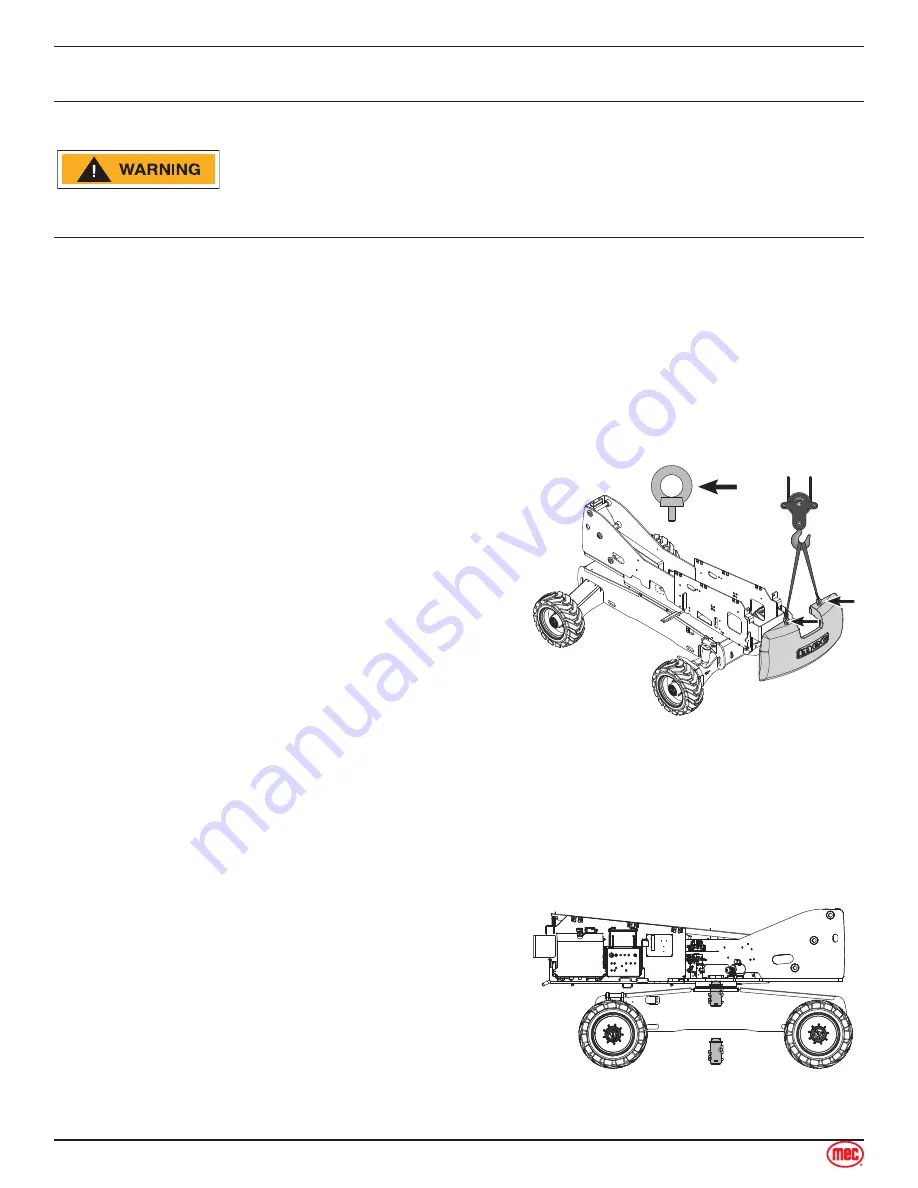

Thread two M24 lifting eyebolts into the machine

counterweight and rig slings as shown. Apply slight

lifting pressure.

1.

2.

3.

4.

5.

ART_4942

M24 Lifting Eye

Minimum

30 mm length

Remove the four bolts that secure the counterweight to the machine turntable.

Remove the counterweight.

Note:

Counterweight Mass: 1980 LBS / 898 KG

Tag and disconnect the hydraulic lines from the top

of the Rotary Manifold.

Tag and disconnect the hydraulic lines from the

bottom of the Rotary Manifold.

Support the Rotary Manifold from below, then

remove the bolts securing the Rotary Manifold in

place.

Remove the Rotary Manifold.

Note:

Rotary Manifold Mass:

75 LBS

34 KG

8.

9.

10.

11.

ART_4944

Rotary

Manifold

6.

7.