Page 110

65-J Desel - Servce & Parts Manual

February 2021

Secton 19 - Troubleshootng

Troubleshooting Chart

The following chart describes the possible causes for inoperation of the different functions of this

machine. The Causes and Solutions columns list various points of references that can be found in the

Hydraulic, Electrical, Schematics and Troubleshooting sections of this manual.

The majority of electrical troubleshooting on this model will require the use of the onboard EZ-Cal

scan tool, located inside the lower control box door. Please refer to “EZ-Cal Scan Tools” on page 99

for further instructions on the use of the EZ-Cal scan tool.

Perform a full assessment of machine operations prior to troubleshooting this model and using this

chart. This model is operated by a Microprocessor Control System equipped with a variety of built-

in safety interlocks to prevent continued operation in the event of a failure or misoperation. Some

interlocks may only be detected through the use of the EZ-Cal.

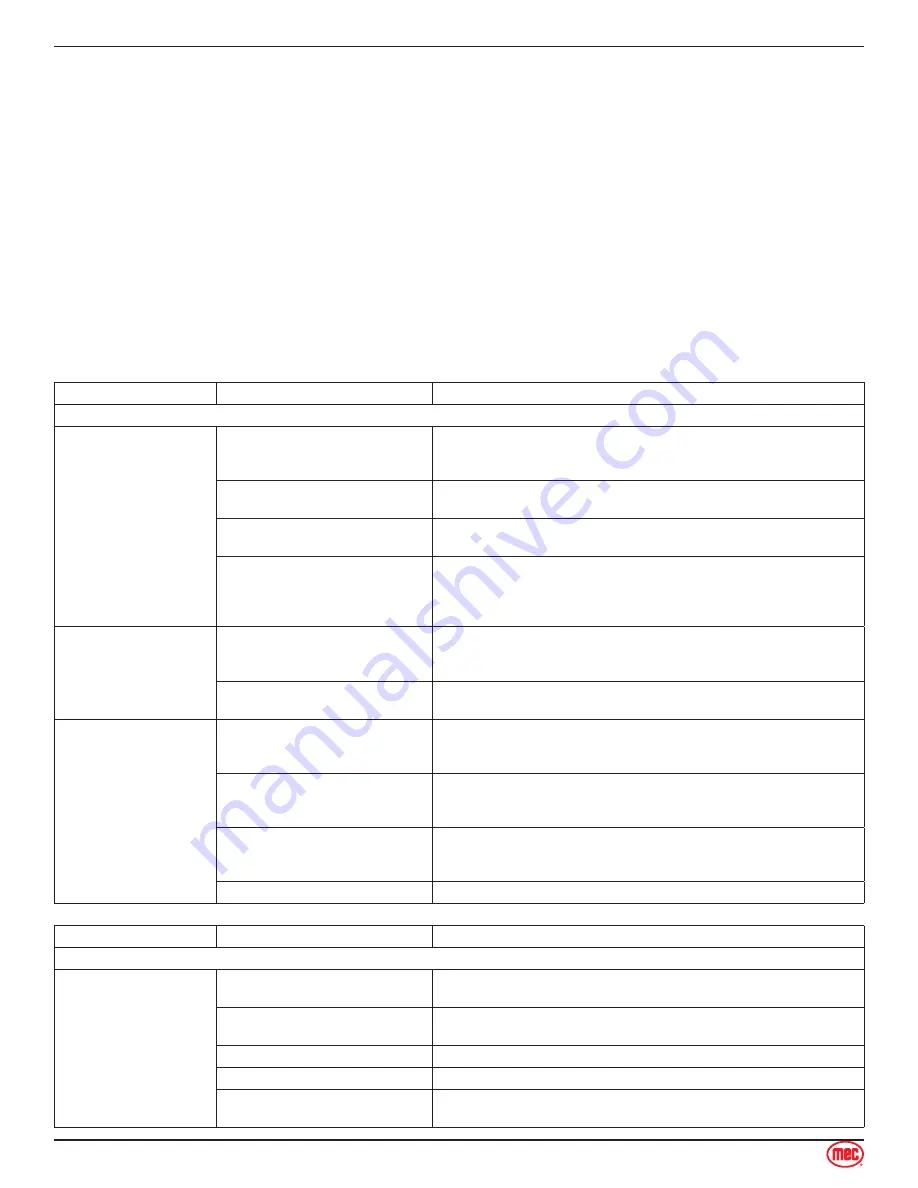

Problem

Possible Cause

Remedy/Solution

General Power Issue

No operation from upper

or lower control station.

No LEDs on modules.

Emergency stop switch pushed

in or ignition switch turned off or

faulty switches

Lower e-stop switch and ignition switch will cut all power.

Upper e-stop will cut only upper power as will the ignition switch in

platform control box.

Battery discharged or faulty

cables

Will receive 4-4 or 7-7 flash on GP400. Clean, service and charge

battery. Repair cables.

Circuit breaker tripped

Located in lower control box. Look for short circuit and/or damage in

wiring or high amperage draw at valve coils or engine actuators.

Faulty Terminal Block Module

(TBM)

Located inside the lower control box. Initiates all power when signaled

by the key switch. Check for loose terminals.

Terminal 4 is Common power from Circuit breaker.

Terminals 1 and 2 are signals to close the relay.

No operation from upper

or lower control station

Module LEDs on or

flashing

Flash codes are the GP400’s

indication of a fault in the system.

Refer to flash code designation in this section of the manual or plug

in an EZ-Cal scan for more relevant information relating to the failure.

See EZ-Cal Instructions for more information.

Starter Relay or Starter failure

Test for signal and Common power to Starter Relay. Check fuse for

Common power to relay. Test Starter.

Operates from lower

controls but not from

upper controls. No LEDs

when in Upper control

position.

Base/Platform select switch not

in Platform position or switch

malfunction

Ensure that the switch is in the Platform position. Check switch

function.

Damaged or loose harness

connections to upper control box

Check for power inside the upper control box on e-stop switch and

at Buss Module. Check for presence of ground on the Ground Buss

Module. Repair connections.

Malfunctioning GP440 Module

(Module inside the upper control

box)

Check help messages using the EZ-Cal tool. Also check for joystick

inputs (see 2C2 and 2D2 Diagnostic Chart for inputs from GP440).

System interlock

Check EZ-Cal HELP messages for interlock

Problem

Possible Cause

Remedy/Solution

Engine Related Issues

Starter will not crank

from upper or lower

stations

Battery discharged or faulty

cables

Will receive 4-4 flash on GP400. Clean, service and charge battery.

Repair cables.

Malfunctioning start relay or fuse

Test/replace relay located on left hand side of engine and fuse located

near starter

Malfunctioning starter

Test/replace starter

Faulty start switch either location

Test/replace as necessary

Starter interrupt system initiated

Check for red “Start Disable” light on lower panel. Starter may be

operated for 10 seconds before a 30 second “cool down” is initiated.