28000

12MXT

M1

57

13. Parts list of the electric diagram

BP

-

Dehydrator pressure switch

B1

-

Load overload pressure switch

B2

-

Load overload pressure switch

B3

-

Stop lights pressure switch

B4

-

Parking brake pressure switch

B5

-

Proximity detector

B6

-

Engine oil pressure switch

B7

-

Power-assistance oil pressure switch

B8

-

Air filter clogged pressure switch

B9

-

Hydraulic filter clogged pressure switch

B10

-

Cold start coil control pressure switch

E1

-

Cigarette lighter

E2

-

Ceiling light

E3

-

Number plate lighting

E4

-

Front left dipped beam

E5

-

Front right dipped beam

E6

-

Front left main beam

E7

-

Front right main beam

E9

-

Rear working light

E10

-

Front working lights

E11

-

Water temperature probe

E12

-

Fuel gauge

E13

-

Cigarette lighter lighting

E14

-

Fuel gauge / radio

E15

-

Working light

E16

-

Buzzer

F1

-

10 A fuse: Boom, intermediate boom,

coupling of rams and 4th foot-operated ram

F2

-

20 A fuse: Offset, stabilizers and blocks,

Load Sensing, tool unlocking and

hydraulic lock

F3

-

7.5 A fuse: Forward (

F

) and reverse (

R

)

F4

-

Not used

F5

-

3 A fuse: Instrument panel safety

F6

-

7.5 A fuse: Automatic lubricating pump

(option)

F7

-

20 A fuse: Instrument panel power outlet

F8

-

5 A fuse: Engine shut-off relay and Meck

Lock

F9

-

Not used

F10

-

Not used

F11

-

7.5 A fuse: Front windscreen wiper and

washer

F12

-

15 A fuse: Front / rear working lights

F13

-

10 A fuse: Dipper beams

F14

-

10 A fuse: Main beams

F15

-

5 A fuse: Lighting and direction indicators

F16

-

7.5 A fuse: Rear windscreen wiper and

washer

F17

-

15 A fuse: Radio, ceiling light and and

cigarette lighter

F18

-

7.5 A fuse: Hazard warning lights

F19

-

3 A fuse: Resetting and rear windscreen

wiper

F20

-

3 A fuse: Resetting and front windscreen

wiper

F21

-

5 A fuse: Position lights

F22

-

5 A fuse: Oscillation lock

F23

-

Not used

F24

-

7.5 A fuse: Revolving light

F25

-

7.5 A fuse: Horn

F26

-

10 A fuse: Pneumatic seat compressor

F27

-

10 A fuse: F1 / F2 option

F28

-

3 A fuse: Turntable alignment

F29

-

10 A fuse: Manual accelerator (option)

F30

-

7.5 A fuse: Stop light and brake lock

F31

-

15 A fuse: Audible reversing signal and

lights, direction inverter

F32

-

5 A fuse: Engine shut-off relay

F33

-

25 A fuse: Condenser fan supply (air

conditioning)

F34

-

3 A fuse: Rear left position light

F35

-

3 A fuse: Rear right position light

F36

-

25 A fuse: Heating fan supply

F37

-

3 A fuse: Number plate light

F38

-

Not used

F39

-

Not used

F40

-

60 A fuse: Turntable supply

G1

-

12 volt battery

G2

-

Alternator

H1

-

Horn

H8

-

Direction indicators light

H9

-

Position lights light

H10

-

High speed (

I

) light

H11

-

Low speed (

II

) light

H12

-

Reverse (

R

) light

H13

-

Forward (

F

) light

H15

-

Revolving light

H17

-

Audible reversing signal

H18

-

Reversing light

H19

-

Rear left direction indicator

H20

-

Front left direction indicator

H21

-

Rear right direction indicator

H22

-

Front right direction indicator

H23

-

Rear left position light

H24

-

Rear right position light

H25

-

Front right position light

H26

-

Right clearance light

H27

-

Left clearance light

H28

-

Front left position light

H31

-

Stops lights light

H40

-

Not used

J1

-

Instrument panel connector

J3

-

Instrument panel connector

J4

-

Instrument panel connector

J5

-

3-pushbutton module connector

KE

-

Starting relay (air conditioning)

KV

-

Condenser relay (air conditioning)

K1

-

Boom / intermediate boom relay

K2

-

Hydraulic lock relay

K3

-

Forced forward (

F

) relay

K4

-

Ram coupling relay

K5

-

Low speed (

I

) in “Loader function” relay

K6

-

Low (

I

) or high (

II

) speed option relay

K7

-

Direction indicators central unit

K8

-

Starting relay

Summary of Contents for 12 MXT

Page 1: ...HANDBOOK OF REPAIR MANUFACTURER MECALAC SAS...

Page 2: ......

Page 48: ...12MXT 28000 46 M1 13 12 10 14 14 11 9 15 16 7 8 6 3 2 4 18 5 17 1...

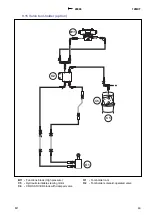

Page 50: ...12MXT 28000 48 M1 Y3 Y2 Y4 Y3A Y5 Y5A Y1 Y10 Y9 Y100 Y8 Y7...

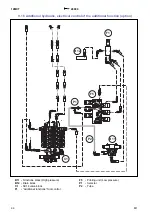

Page 52: ...12MXT 28000 50 M1 Y18 Y17 Y15 Y20 Y19 Y11 Y13 Y12 Y14 Y22 Y21...

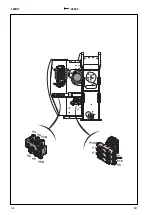

Page 82: ...12MXT 28000 80 M1...

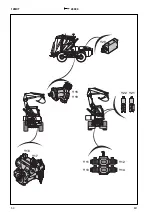

Page 87: ...28000 12MXT M1 85...