F1050/F1200

1-6

1

Safety regulations

1.5.1.21

Only reliable persons may act as guides. They

must be informed of their duties prior to commencing work.

1.5.1.22

The driver and guide must agree on signals for

communication. These signals may only be given by the

driver and guide.

1.5.1.23

The guide must be easily recognizable – e.g. by

wearing warning clothing – and must always be in the

driver’s field of vision.

1.5.1.24

When passing under subways, bridges, tunnels,

electrical overhead lines, etc., make sure that there is

adequate clearance!

1.5.1.25

Maintain adequate clearance when working at

the edge of quarries, pits, rubbish dumps and embank-

ments to eliminate any danger of the machine plunging

down. The contractor or his deputy must stipulate the

distance from the edge, taking the soil bearing capacity

into consideration.

1.5.1.26

The machine may only be used at stationary

dumping areas when firmly integrated installations are

provided to prevent the machine from running or sliding

down.

1.5.1.27

Avoid such work which could have a detrimental

effect on the stability of the machine.

The following may affect the stability:

- overloading,

- ground that is too soft,

- abrupt acceleration or deceleration of driving or working

movement,

- reversing out of a high driving speed,

- working on slopes,

- driving too quickly round sharp bends,

1.5.1.28

Do not traverse across slopes. Always carry

working equipment and loads near the ground, especially

when driving down slopes. Sudden cornering is forbidden!

1.5.1.29

On steep inclines and gradients, the load is to be

carried on the uphill side.

1.5.1.30

Reduce speed before inclines; always adapt the

speed of the machine to the local conditions!

Never

change into low gear when driving on slopes, but

rather before the slope!

1.5.1.31

Reversing over a longer period must be avoided!

1.5.1.32

When leaving the machine, always safeguard the

machine to prevent it from unintentionally rolling away;

prevent non-authorised persons from using it!

1.5.1.33

The driver must not leave the machine if the

attachments are not lowered or safeguarded.

1.5.1.34

During breaks and after work hours, the driver

must park the machine on solid and, if possible, level

ground and safeguard it against unintentionally rolling

away.

Summary of Contents for AF 1050

Page 9: ...Safety regulations...

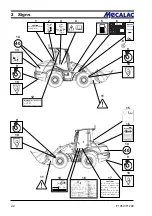

Page 21: ...Signs...

Page 24: ......

Page 25: ...Protection against theft...

Page 28: ...F1050 F1200 3 4 3 Protection against theft...

Page 29: ...Description...

Page 43: ...Operation...

Page 55: ...Attachments...

Page 60: ......

Page 61: ...Rescue towing lashing lifting by crane...

Page 67: ...Maintenance...

Page 69: ......

Page 88: ...F1050 F1200 8 20 8 Maintenance Figure 8 47...

Page 89: ...Circuit diagrams...

Page 114: ......

Page 115: ...Technical Data Equipment...

Page 122: ......

Page 123: ...TechnicalData Attachments...

Page 132: ......

Page 133: ...Optional Extras...

Page 135: ...F1050 F1200 13 3 Optional Extras 13...

Page 136: ...F1050 F1200 13 4 13 Optional Extras...

Page 137: ...F1050 F1200 13 5 Optional Extras 13...

Page 138: ...F1050 F1200 13 6 13 Optional Extras...

Page 139: ...F1050 F1200 13 7 Optional Extras 13...

Page 140: ...F1050 F1200 13 8 13 Optional Extras...

Page 141: ...F1050 F1200 13 9 Optional Extras 13...

Page 142: ...F1050 F1200 13 10 13 Optional Extras...

Page 143: ...F1050 F1200 13 11 Optional Extras 13...

Page 144: ...F1050 F1200 13 12 13 Optional Extras...

Page 145: ...F1050 F1200 13 13 Optional Extras 13...

Page 146: ...F1050 F1200 13 14 13 Optional Extras...

Page 147: ...F1050 F1200 13 15 Optional Extras 13...

Page 148: ...F1050 F1200 13 16 13 Optional Extras 23131461 KL C 31632...