F1050/F1200

1-10

1

Safety regulations

1.6.1.4

Work on the electrical system or on the operating

system may only be carried out by a skilled electrician or

by personnel instructed or supervised by such a trained

electrician according to electrotechnical regulations.

1.6.1.5

The electrical installation of a machine must be

reviewed/inspected at regular intervals. Any defects, e.g.

loose connections or scorched cabling, must be eliminated

immediately.

1.6.1.6

The main battery switch must be disconnected

before inspection, maintenance or repair of machine parts

and components so that they are not under power.

1.6.1.7

Electric welding operations may only be per-

formed if the main battery switch has been removed.

1.6.2

Hydraulics

1.6.2.1

Only experts with special expertise and experience

may carry out work on the hydraulic system!

1.6.2.2

All pipelines, hoses and screw connections must

be checked regularly for leakages and visible damage!

Immediately repair such defects! Spurting hydraulic oil

may cause injuries and fire.

1.6.2.3

Those hydraulic system segments which are to

be opened must be depressurised before commencement

of the repair work according to the assembly group descrip-

tion!

1.6.2.4

The hydraulic pipelines must be correctly laid and

connected! Do not mix up the connections. Spare parts

must meet the technical requirements of the manufacturer.

Original spare parts ensure the fulfilment of these require-

ments.

1.6.2.5

The factory settings of hydraulic components

(e.g. the maximum permissible speed of the axial piston

engine) must not be altered. Any adjustment will render the

warranty invalid.

1.6.3

Noise

Sound protection equipment must be in the protective

position during operation of the machine.

1.6.4

Oil, grease and other chemical sub-

stances

1.6.4.1

The relevant safety regulations must be observed

when handling oil, grease or other chemical substances.

1.6.4.2

Caution when working with hot fuel and other

accessory materials (danger of burning and scalding).

Summary of Contents for AF 1050

Page 9: ...Safety regulations...

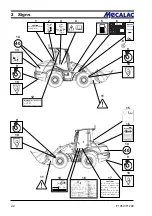

Page 21: ...Signs...

Page 24: ......

Page 25: ...Protection against theft...

Page 28: ...F1050 F1200 3 4 3 Protection against theft...

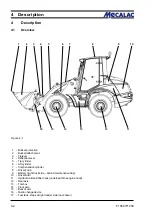

Page 29: ...Description...

Page 43: ...Operation...

Page 55: ...Attachments...

Page 60: ......

Page 61: ...Rescue towing lashing lifting by crane...

Page 67: ...Maintenance...

Page 69: ......

Page 88: ...F1050 F1200 8 20 8 Maintenance Figure 8 47...

Page 89: ...Circuit diagrams...

Page 114: ......

Page 115: ...Technical Data Equipment...

Page 122: ......

Page 123: ...TechnicalData Attachments...

Page 132: ......

Page 133: ...Optional Extras...

Page 135: ...F1050 F1200 13 3 Optional Extras 13...

Page 136: ...F1050 F1200 13 4 13 Optional Extras...

Page 137: ...F1050 F1200 13 5 Optional Extras 13...

Page 138: ...F1050 F1200 13 6 13 Optional Extras...

Page 139: ...F1050 F1200 13 7 Optional Extras 13...

Page 140: ...F1050 F1200 13 8 13 Optional Extras...

Page 141: ...F1050 F1200 13 9 Optional Extras 13...

Page 142: ...F1050 F1200 13 10 13 Optional Extras...

Page 143: ...F1050 F1200 13 11 Optional Extras 13...

Page 144: ...F1050 F1200 13 12 13 Optional Extras...

Page 145: ...F1050 F1200 13 13 Optional Extras 13...

Page 146: ...F1050 F1200 13 14 13 Optional Extras...

Page 147: ...F1050 F1200 13 15 Optional Extras 13...

Page 148: ...F1050 F1200 13 16 13 Optional Extras 23131461 KL C 31632...