P070/P071/P085/P086/P100/P101

1-5

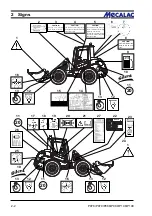

Safety regulations

1

1.5.1.9

Avoid any action which appears to be dangerous!

1.5.1.10

Persons must not be carried in the working

equipment, e.g. in the attachments!

1.5.1.11

The operator may carry out work with the machine

only if no persons are in the danger zone.

The danger zone is the area near the machine where

persons may be injured

- by work-induced movements of the machine,

- by work attachments and devices,

- by loads swinging out,

- by dropping loads,

- by attachments falling down from the machine.

1.5.1.12

In case of danger to persons the operator must

give appropriate warning signs. It may be necessary to

stop work.

1.5.1.13

In case of functional defects, stop the machine

immediately

and secure it. Eliminate defects immediately!

1.5.1.14

Check the machine at least once every shift for

external visible damage and defects. Report any defects

(including changes in the operational behavior) imme-

diately to the person in charge. If necessary stop the

machine immediately and safeguard it.

1.5.1.15

The driver may slew the attachments in overhead

driving, operating and working areas only if these areas are

suitably safeguarded by protective roofing. These protec-

tion roofs must offer appropriate safety against loads and

falling goods. If you are in doubt, assume

no

protection

roofs are present.

1.5.1.16

When driving, the attachment is to be kept as

close to the ground as possible.

1.5.1.17

Please observe the applicable traffic regulations

when driving on public roads, paths or open spaces. The

machine must be brought into road-worthy condition be-

forehand.

1.5.1.18

Make sure to always switch on lights in poor

visibility and during darkness.

1.5.1.19

If the lights of the machine are not adequate for

the safe execution of certain work, additional lighting must

be provided on the working site, especially at dumping

points.

1.5.1.20

Should the driver’s sight of his driving and working

area be restricted due to work-induced influences, he must

be given guidance or he must safeguard the working area

by a firm barrier.

Summary of Contents for AX 1000

Page 9: ...Safety regulations...

Page 21: ...Signs...

Page 24: ......

Page 25: ...Protectionagainsttheft...

Page 28: ......

Page 29: ...Description...

Page 43: ...Operation...

Page 53: ...Attachments...

Page 58: ......

Page 59: ...Rescue towing lashing lifting by crane...

Page 66: ......

Page 67: ...Maintenance...

Page 83: ...Faults causes and remedies...

Page 86: ......

Page 87: ...Circuit diagrams...

Page 97: ......

Page 100: ......

Page 101: ...Technical data loader...

Page 111: ...Technical data attachments...

Page 124: ......

Page 125: ...Additional options modifications Notes on inspection for loaders...

Page 127: ...P070 P071 P085 P086 P100 P101 13 3 Additionaloptions modfications 13...

Page 128: ...P070 P071 P085 P086 P100 P101 13 4 13 Additionaloptions modfications...

Page 129: ...P070 P071 P085 P086 P100 P101 13 5 Additionaloptions modfications 13...

Page 130: ...P070 P071 P085 P086 P100 P101 13 6 13 Additionaloptions modfications...

Page 131: ...P070 P071 P085 P086 P100 P101 13 7 Additionaloptions modfications 13...

Page 132: ...P070 P071 P085 P086 P100 P101 13 8 13 Additionaloptions modfications...

Page 133: ...P0700 P0710 P0850 P0860 P1000 P1010 Index i Index...

Page 134: ...P0700 P0710 P0850 P0860 P1000 P1010 Index ii Index...

Page 135: ...P0700 P0710 P0850 P0860 P1000 P1010 Index iii Index...

Page 136: ...P0700 P0710 P0850 P0860 P1000 P1010 Index iv Index...

Page 137: ...P0700 P0710 P0850 P0860 P1000 P1010 Index v Index...

Page 138: ...P0700 P0710 P0850 P0860 P1000 P1010 Index vi Index...

Page 139: ...P0700 P0710 P0850 P0860 P1000 P1010 Index vii Index...

Page 140: ...P0700 P0710 P0850 P0860 P1000 P1010 Index viii Index...

Page 141: ...P0700 P0710 P0850 P0860 P1000 P1010 Index ix Index...

Page 142: ...P0700 P0710 P0850 P0860 P1000 P1010 Index x Index...

Page 143: ...P0700 P0710 P0850 P0860 P1000 P1010 Index xi Index...

Page 144: ...P0700 P0710 P0850 P0860 P1000 P1010 Index xii Index 23128003 Index 0...