P0700/P0710/P0850/P0860/P1000/P1010

4-3

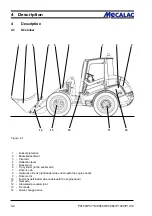

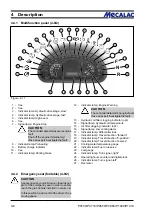

Description

4

Figure 4-2

4.2

Loader

Undercarriage

The axial piston pump for the hydraulic drive is driven by

the diesel engine. Pressure hoses for extremely high

pressure connect the axial piston pump with the axial piston

engine. The axial piston engine is flanged to the distribution/

intermediate gear of the rear axle (with planetary gear). The

distribution/intermediate gear transmits the torque of the

axial piston engine directly to the rear axle and to the front

axle (with planetary gear).

CAUTION

The maximum speed of the axial piston engine is

governed by settings made at the factory. Any

adjustment will render the warranty invalid.

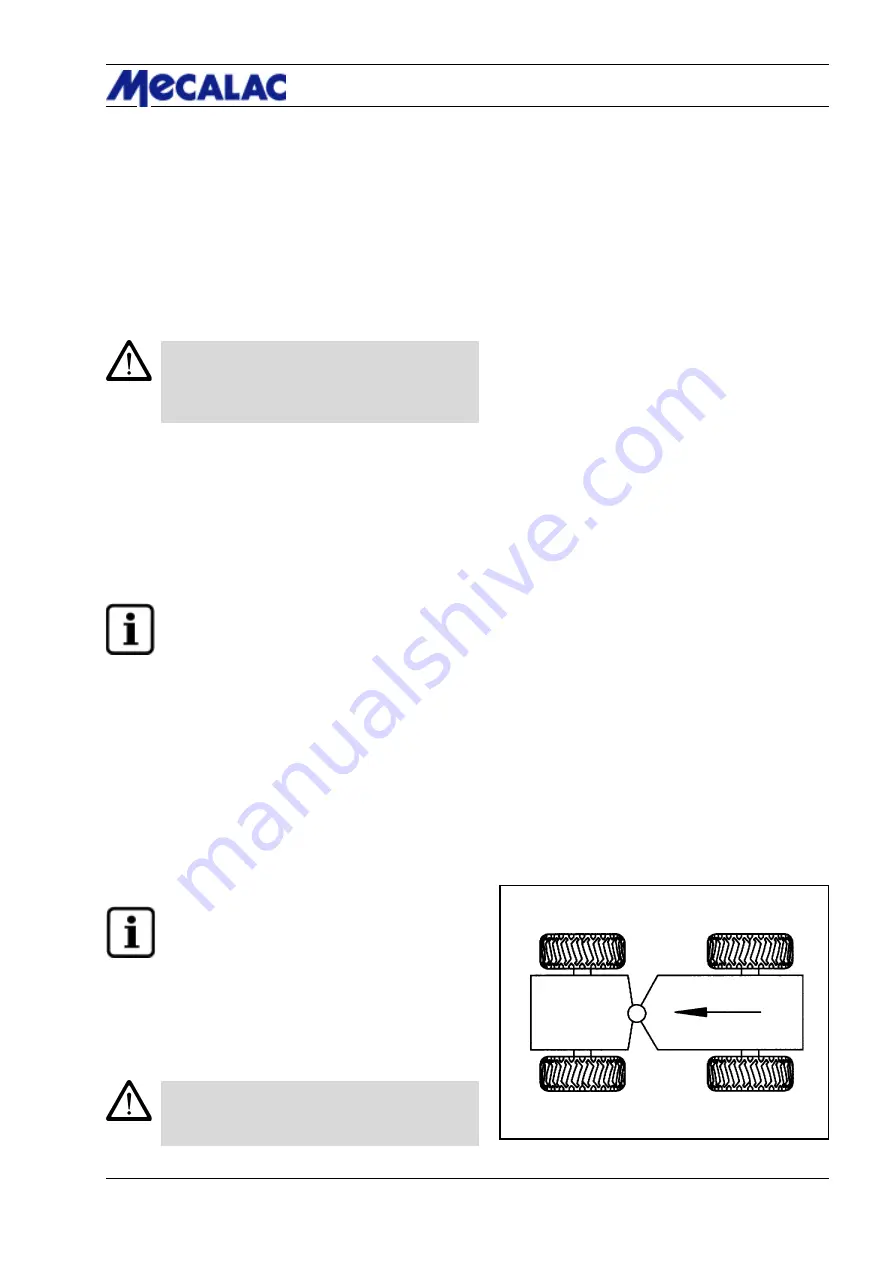

Tyres

The following tyres are permitted:

12.5/80 R18

15.5/55 R18

365/70 R18

405/70 R18

425/55 R17

For the running direction, see Fig. 4-2.

NOTE

All four tyres must be identical and have the same

PR rating (PR = ply rating: number of textile plies).

Steering system

The power for the hydrostatic steering system is supplied

via a priority valve from a gear-type pump. With a minimum

of effort on the steering wheel, the oil flow is directed by a

steering unit into the steering cylinder.

Emergency steering

The hydrostatic steering system can also be used in a

limited way if the diesel engine fails. The loader can be

steered using a considerable amount of manual effort.

NOTE

See chapter 7, “Towing the loader”.

Differential lock

To enhance the traction of soft slippery ground, you can

enable the differential lock acting on all four wheels by

pressing pushbutton (4-10/10) and keeping it pressed.

CAUTION

Enable the differential lock only when the loader

is at a standstill.

Summary of Contents for AX 1000

Page 9: ...Safety regulations...

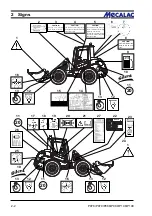

Page 21: ...Signs...

Page 24: ......

Page 25: ...Protectionagainsttheft...

Page 28: ......

Page 29: ...Description...

Page 43: ...Operation...

Page 53: ...Attachments...

Page 58: ......

Page 59: ...Rescue towing lashing lifting by crane...

Page 66: ......

Page 67: ...Maintenance...

Page 83: ...Faults causes and remedies...

Page 86: ......

Page 87: ...Circuit diagrams...

Page 97: ......

Page 100: ......

Page 101: ...Technical data loader...

Page 111: ...Technical data attachments...

Page 124: ......

Page 125: ...Additional options modifications Notes on inspection for loaders...

Page 127: ...P070 P071 P085 P086 P100 P101 13 3 Additionaloptions modfications 13...

Page 128: ...P070 P071 P085 P086 P100 P101 13 4 13 Additionaloptions modfications...

Page 129: ...P070 P071 P085 P086 P100 P101 13 5 Additionaloptions modfications 13...

Page 130: ...P070 P071 P085 P086 P100 P101 13 6 13 Additionaloptions modfications...

Page 131: ...P070 P071 P085 P086 P100 P101 13 7 Additionaloptions modfications 13...

Page 132: ...P070 P071 P085 P086 P100 P101 13 8 13 Additionaloptions modfications...

Page 133: ...P0700 P0710 P0850 P0860 P1000 P1010 Index i Index...

Page 134: ...P0700 P0710 P0850 P0860 P1000 P1010 Index ii Index...

Page 135: ...P0700 P0710 P0850 P0860 P1000 P1010 Index iii Index...

Page 136: ...P0700 P0710 P0850 P0860 P1000 P1010 Index iv Index...

Page 137: ...P0700 P0710 P0850 P0860 P1000 P1010 Index v Index...

Page 138: ...P0700 P0710 P0850 P0860 P1000 P1010 Index vi Index...

Page 139: ...P0700 P0710 P0850 P0860 P1000 P1010 Index vii Index...

Page 140: ...P0700 P0710 P0850 P0860 P1000 P1010 Index viii Index...

Page 141: ...P0700 P0710 P0850 P0860 P1000 P1010 Index ix Index...

Page 142: ...P0700 P0710 P0850 P0860 P1000 P1010 Index x Index...

Page 143: ...P0700 P0710 P0850 P0860 P1000 P1010 Index xi Index...

Page 144: ...P0700 P0710 P0850 P0860 P1000 P1010 Index xii Index 23128003 Index 0...